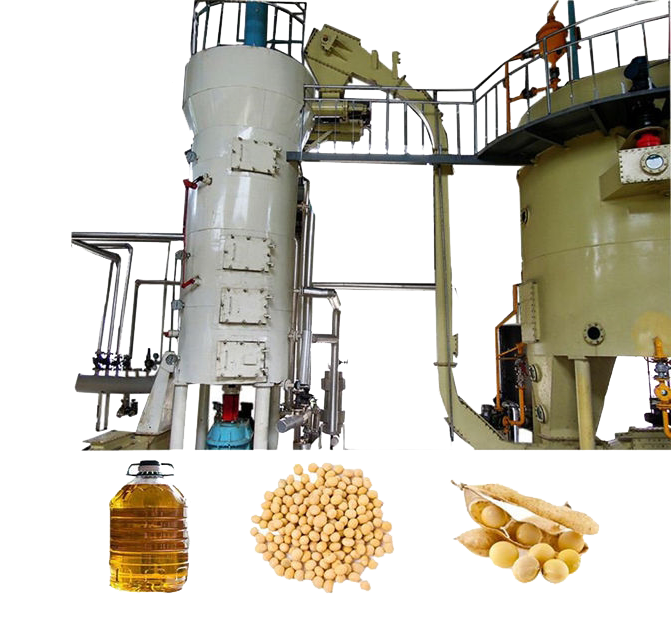

Soybean oil solvent extraction machine adopts the most scientific oil extracting method to extract crude soybean oil from soybean meal. The advanced designed production of soybean oil solvent extraction technology provides the high capacity soybean edible oil extraction with low solvent addition.

Processing Capacity: 20-2000T/D

Processing Capacity: 20-2000T/D Processing Material: soybean

Processing Material: soybean

all machine can be customized according to customers' needs.

New type soybean oil solvent extraction technology utilizes solvent to extract oil out of soybean embryos through effects of wet penetration, diffusion and convert diffusion. The solvent capable of dissolving the fat separates soybean oil from the mixture of oil and solvent, and obtains crude soybean oil after solvent recycled. The solvent among soybean meal is also recycled so as to obtain extracted soybean meal.

● Scientific soybean oil extraction design with lowest solvent addition. We adopts vacuum evaporation, and solvent soaking or spaying method to extract soybean crude oil from soybean with high oil yield and low residual oil in soybean meal.

● Environmental protective exhausted gas absorption system. There are complete sets of exhausted gas absorption system equipped with all process flow of oil extraction. This soybean oil extraction project is featured by low pollution, low energy consumption, low failure rate and stable operation.

● Rice experience with turnkey soybean oil extraction. We owns rice experience of design, manufacturing and installation of soybean edible oil extraction plant with guaranteed high efficiency, high profit and reliable extraction process.

QIE Machinery is a professional soybean oil mill plant machine manufacturer. We can provide soybean oil expeller machine, large scale soybean oil mill plant, automatic soybean oil mill plant and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

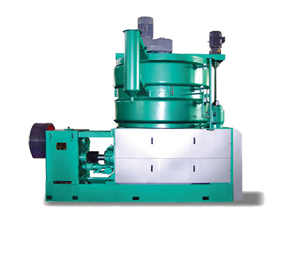

Rotocel extractor adopts chain transmission, unique rotor balance design,with advantages of low rotate speed, small power,stable operation,no noise, low maintenance cost.

Working principle: Adopt organic solvent N-hexane to extract oil through soaking or spraying to get miscella. Separate solvent from oil through evaporating and stripping according to different boiling points between volatile solvent and non-volatile oil to get crude extracted oil. Solvent can be recycled through condensation and separation. Wet meal is separated out through hydraulic cyclone and is conveyed to D.T.D.C.

Advantages: 1).Low rotate speed, small power consumption,good sealing property,stable operation,no noise, low maintenance cost. 2). Reduce input of fresh solvent, reduce residual oil rate in meal, improve miscella concentration, achieve energy-saving purpose. 3).Improve crude oil quality and reduce scaling of evaporation system.

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

Rotory type extraction machine (Rotocel Extractor) in widely used with pre-pressured oil cakes. It has a rotating cell design at the top bin level which makes immersion extraction easy and reduces the number of meal fines in the Miscella. This improves the quality of crude oil by the reduced scaling in evaporation system. This extractor is driven by gear rack. The unique extractor is designed to reduce power consumption, lower maintenance cost and reduce noise. We remain dedicated to design, supply and service all your extraction needs, set up workshops on oil extraction and turn around your output from 100 to 6000T a day.

This extractor uses a chain drive system. It is suitable for the extraction of high oil content as well as direct extraction from low content oil materials. As with the rotorcel extractor, loop type extractor has been designed to increase efficiency by reducing fuel consumption, lower maintenance cost and reduces noise. For efficient processing, the extractor utilizes percolation-style filtration. Also, rotation occurs at the bend of the machinery to improve the output. Specialized self solvent spraying ensure the best extraction effects. A special material used for discharging the system and its adjustable speed ensures even discharge of extract into conveyor carriages and a buffering impact to the conveyor. This ensures a stable desolvenizing process.

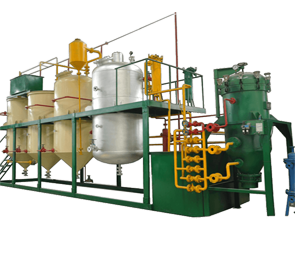

To meet every client's requirements, we offer a wide range of soybean oil milling equipment of different capacities of 300kg to 100 metric tons. Refined soybean oil belongs to different grades, varying from grades 1-2. There are two types of technologies used, the batch technology and continuous technology. For capacities less than 20 t/d, we normally use the batch technology, otherwise semi continuous or continuous process is adopted.

We are committed to researching new and efficient requirements. QIE Machinery develops soybean oil milling machinery intended to be fully automatic that utilizes advanced technology that can be applied to suit clients' requirements.

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

Solvent extraction is a multi-stage process optimized for maximum oil recovery:

Pre-treatment: Soybeans are cleaned, dehulled, and flaked into thin sheets (0.2–0.4 mm thick) to increase surface area for solvent contact.

Extraction: Flakes are fed into a percolation extractor (e.g., rotary drum or countercurrent column) where food-grade hexane is circulated. The solvent dissolves oil, forming a “miscella” (oil-hexane mixture).

Meal desolventizing: Spent soybean flakes (now low in oil) are sent to a desolventizer-toaster (DT), where steam heats them to remove residual solvent (to <0.1%). The meal is then cooled and sold as animal feed.

Miscella distillation: The oil-hexane mixture is heated in a distillation tower under vacuum to evaporate hexane (which is condensed and recycled for reuse).

Oil stripping: Final traces of solvent are removed from crude oil via steam stripping (200–220°C under vacuum), resulting in crude soybean oil ready for refining.

Maintenance varies by machine type but focuses on preserving efficiency and safety:

Mechanical/expeller machines:

Daily: Clean screw and cage to remove meal buildup; check for oil leaks.

Weekly: Lubricate bearings and gears with food-grade grease; inspect screw flights for wear (replace every 3–6 months for industrial use).

Monthly: Adjust screw-to-cage gap to maintain pressure; calibrate temperature sensors.

Solvent extraction machines:

Daily: Clean extractor screens to prevent clogging; check solvent levels and recovery rates.

Weekly: Inspect distillation tower trays for fouling; test solvent vapor detectors.

Monthly: Calibrate solvent flow meters and temperature controls; replace carbon filters in vapor recovery units.

Quarterly: Overhaul solvent pumps and check for leaks in hoses/pipes; clean DT unit steam injectors.

Both types require annual full-system audits (e.g., checking for corrosion in solvent tanks, verifying mechanical alignment) to prevent failures.

Residual oil content (ROC) is the amount of oil left in meal after extraction, and it directly impacts meal value:

Mechanical extraction: ROC is 2–3%—the meal is still high in protein (45–50%) but less valuable for feed manufacturers, as excess oil can reduce shelf life and cause digestive issues in livestock.

Solvent extraction: ROC is 0.5–1%—this “low-oil meal” is premium, fetching 10–15% higher prices because it’s more stable, easier to store, and better suited for high-protein feed formulations (e.g., poultry or aquaculture feed).

For large facilities, even 1% lower ROC translates to thousands of dollars in additional annual revenue from meal sales—making solvent extraction economically viable despite higher upfront costs.

Recent innovations focus on reducing environmental impact and boosting performance:

Solvent alternatives: Development of non-flammable, biodegradable solvents (e.g., ethanol or supercritical CO₂) to replace hexane—though these are still costly for large-scale use.

Energy recovery: Solvent machines now integrate heat exchangers to capture waste heat from distillation and DT units, reducing natural gas use by 20–30%.

Mechanical efficiency: New expeller designs (e.g., dual-screw presses) increase yield by 5–8% compared to single-screw models, narrowing the gap with solvent extraction.

Digital controls: PLC systems with AI algorithms adjust extraction parameters (e.g., solvent flow, screw speed) in real time based on soybean quality, optimizing yield and reducing energy waste.

Waste reduction: Solvent machines now recover 99.9% of hexane (vs. 99.5% a decade ago), minimizing emissions and solvent purchases. Mechanical machines generate less meal dust, reducing waste and improving air quality.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.