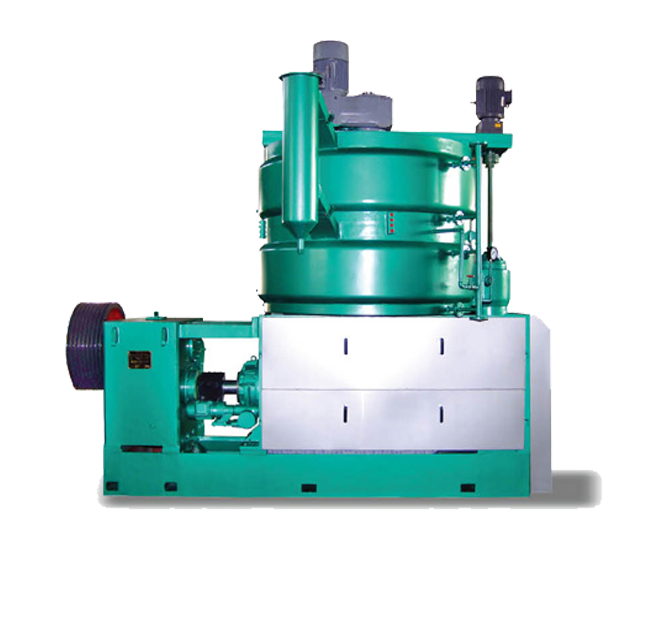

The professional large soybean oil press is continuous oil extraction machine. In medium-sized and large-sized soybean oil plant, continuous pre-pressing machine is a popular equipment for pre-squeezing and leaching process. This pre-pressing machine has advantages of the reasonable transmission gear, compact structure, and small footprint. And the machine has achieved improvements in the aspects of steaming, dehydrating, uniform feeding, mechanical wringing, and squeezing cage loading and unloading.

Processing Capacity: 10-300T/D

Processing Capacity: 10-300T/D Residual oil rate: 6-8%

Residual oil rate: 6-8%

all machine can be customized according to customers' needs.

Large Soybean Oil Press Machine characteristics have suited to pre-press sunflower seed oil. Under normal pre-pressing conditions, its features are:

* The machine is made up of stainless steel. The use of high-quality steel carburizing heat treatment can greatly extend the service life of the equipment.

* Large capacity, small workshop area, low power consumption, less operation management and maintenance work.

* The structure of the pre-squeezed cake is loosened but not crushed, which is favorable for the solvent to permeate when leaching; And the oil content and water content of the squeezed cake are suitable for solvent extraction.

The quality of squeezed oil is better than that of squeezing or leaching once.

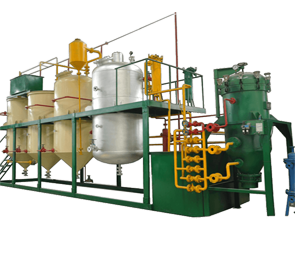

QIE Machinery is a professional soybean oil mill plant machine manufacturer. We can provide soybean oil expeller machine, large scale soybean oil mill plant, automatic soybean oil mill plant and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

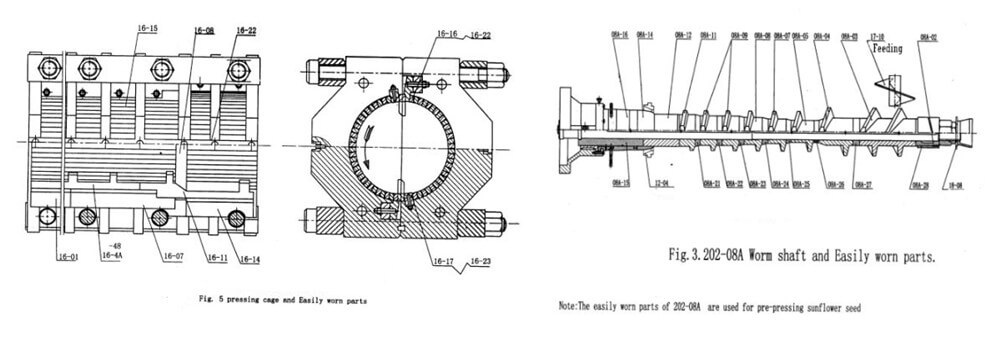

Our Large Soybean Oil Press Machine is made up of the following main components: steamer, feeding mechanism, squeezing cage, squeezing screw shaft (including the cake adjustment mechanism) and transmission.

This equipment is a vertical three-tier steamer, similar to a typical vertical auxiliary steamer, mounted on a bracket of the frame. Its drive motor is included in the total driveline and steaming can adjust the temperature and moisture of the raw material before it enters the press chamber so that it reaches the requirement of pressing.

The working part of the feeding mechanism is between the discharge port of the steamer and the feeding end of the squeezing shaft. It consists of the squeezing shaft with screw blades at the lower end and the falling cylinder. The entrance of the cylinder has a rotary control valve for controlling the falling flow. There is a hopper under the valve, from which the falling conditions can be observed and the material could be taken out as samples during pressing.

The squeezing cage and squeezing screw shaft are the main components of this equipment. Firstly, the material is pressed down by the feeding mechanism and continuously enters into the space between the squeezing cage & the squeezing screw shaft (called squeezing chamber). Due to the rotation of the squeezing screw shaft and the squeezing chamber gradually reduce the gap, the material is under intense pressure and most of which is pressed out of oil, next, the oil would flow out through the gap of squeeze cage.

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

Expertise and Experience: Decades of experience in soybean oil processing equipment manufacturing and technology innovation.

Customization: Our Large Soybean Oil Press Machines can be tailored to meet specific capacity requirements and raw material types.

Comprehensive Service: From soybean oil mill plant consultation, designing, and installation to training and after-sales support, we provide complete solutions for our customers.

Global Reach: Our soybean oil extraction machines are trusted by clients worldwide, and we offer international delivery and service.

After-Sales Support: We provide on-site installation support to ensure seamless setup and integration into your soybean oil production line.

Comprehensive training is provided for your team to operate and maintain the machine effectively. Our dedicated team is available to address any operational issues or queries promptly.

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

Large presses require fully integrated pre-treatment lines to handle high volumes and ensure optimal yield—standalone pre-treatment is impractical.

Essential upstream equipment includes:

Continuous cleaning systems: Multi-stage units with vibratory sieves, magnetic separators (to remove metal), and air classifiers to eliminate 99% of impurities (stones, dirt, broken seeds) that damage the press or contaminate oil.

Industrial dehullers: High-speed impact or friction dehullers that remove 95%+ of soybean hulls (2–3% of weight) and separate hulls via air sorting. Hulls are diverted to biomass boilers (for energy) to avoid clogging the press.

Roller flaking mills: Heavy-duty rollers that crush soybeans into thin, uniform flakes (0.2–0.4 mm thick) at 1,000–5,000 kg/h. Flaking increases surface area by 200–300%, boosting oil extraction efficiency by 5–8%.

Conditioning towers: Vertical chambers that adjust soybean moisture to 8–10% using heated air and steam. Consistent moisture prevents clogging, ensures even compression, and protects the press from wear.

These systems operate in sync with the press via PLC controls, ensuring a steady flow of properly prepared soybeans—any disruption in pre-treatment can halt press operation and cause costly downtime.

Large soybean oil press machines produce 780–820 kg of soybean meal per 1,000 kg of soybeans (since 180–220 kg is extracted as oil). This meal—rich in protein (45–50%)—is a high-value byproduct used in livestock, poultry, and aquaculture feed.

Cooling: Continuous belt coolers that reduce meal temperature from 80–90°C to 25–30°C to prevent mold growth and preserve nutrients.

Grinding: Hammer mills that reduce meal pellets to a uniform powder (particle size: 1–3 mm) as required by feed manufacturers.

Screening: Sifters that remove oversized particles to ensure consistency, which is critical for feed mixing.

Storage: Silos with climate control (10–15°C, <65% humidity) to store meal until shipment.

For large facilities, meal often generates 30–40% of total revenue—making its quality and consistency as important as oil yield. Large presses produce dense, low-moisture meal (8–10% moisture) that is easier to store and transport than meal from smaller presses.

Capacity varies by model:

Advanced models include:

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.