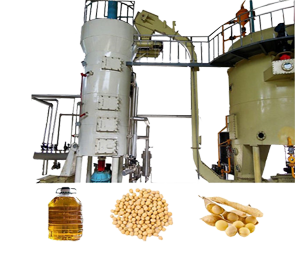

The integrated soybean oil press machine with filter has the advantage of higher efficiency, lower consumption, simple operating, stable function, easy maintenance, high productivity and high oil output. It is widely used in the edible oil factory, oil mill plant, and privates edible oil production workshop. What's more, each integrated soybean oil press machine can be combined together with other soybean oil machines to improve working efficiency and oil yield.

Processing Capacity: 1-30T/D

Processing Capacity: 1-30T/D Residual oil rate: 6-8%

Residual oil rate: 6-8%

all machine can be customized according to customers' needs.

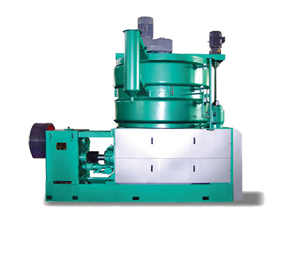

Integrated soybean oil press machine, actually, is a type of screw oil expeller that is improved in some functions for convenience uses and higher oil output. The added functions for automatic oil press machine are reflected on the design of its structure. Generally, it is composed of material feeder, pressing chamber, electric control cabinet and filters. And, these automatic oil press machines equipped with vacuum filters are automatic oil press machine with vacuum filters.It is clear that the differences between automatic oil press machine with filters and screw oil press is the Electric Control Cabinet and Vacuum Filters. The electric control cabinet provides more accurate display for the oil pressing technology and the vacuum filters can directly filter extracted oil automatically for pure oil. These functions are very convenient and time saving in practical uses.Therefore, automatic oil press machine with vacuum filters are more and more popular among bazaars, country market, mini oil mill, small oil production workshops and medium oil processing factory!

Integrated screw oil press is one of the advanced oil presses, it can be widely used for squeezing sesame, rapeseed, peanut kernel, cottonseed, soybean, olive, tea seed and corn germ etc.

QIE Machinery is a professional small soybean oil mill plant manufacturer. We can provide soybean oil press machine, small scale soybean oil mill plant, soybean oil production line and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

1. High oil yield: this automatic screw oil press adopts directional compression, multistage propulsion, and once-squeezing, the oil yield can increase 10% —30%.

2. Large production quantity: the working efficiency can be improved more than 30% by strengthening the feed system and increasing the propulsion speed.

3. Automatic control: this oil press can control the squeezing temperature automatically; built-in vacuum shunt can make the efficient separation of oil and residue.

4. Safe and convenient: simple structure covering small space; adopt totally enclosed protection to ensure safe and convenient operation.

5. Reliable and durable: adopt quality steel and fatigue-resisting castings to ensure reliable performance, which can realize long time and continuous running; the surface of automatic screw oil press adopts electrostatic spraying, which can resist over-high temperature, clean and delicate.

◆Pure oil: vacuum filtering device of the automatic screw oil press can ensure the pure oil conforming to the health and quarantine standard.

◆Saving of labor: this oil press can save 60% labor with the same output, one or two people can produce oil by using the oil press.

◆Energy conservation: automatic screw oil press can decrease 40% power with the same output.

◆Wide usage: the popular automatic screw oil press machine can press multiple oil crops, high oil yield and large capacity.

◆No temperature limit: this machine is equipped with a temperature control system, the crude oil temperature can be adjusted naturally to achieve quick pure filtration. So it won’t be limited by the seasons or climate.

When the oil press runs, the processed oil materials enter into the squeezing chamber through the hopper. The screw rotor propels the oil materials inward and squeezes them. The oil materials in the squeezing chamber are motorial. In the high-pressure chamber, there is great friction resistance between oil materials and squeezing the spiral or squeezing chamber, thus the micro materials can create friction. On the other hand, the squeezing screw diameter is gradually thickening and the screw pitch is gradually decreasing, so when the squeezing screw rotates, the screw threads can propel the oil materials forward or outward. The heat generated by friction can improve the yield of the oil press, and let the oil flows from the gaps.

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

High Performance-price Ratio: It not only inherits the advantages of screw oil press, but increase the functionality without complexity for more smooth oil pressing process and higher oil extraction yield.

Small Floor Space: With compacting structure, it covers small land. Just 10~20 square meters can run your machines or setup a small oil workshop.

Wide Applicability: It can be used to process a very wide range of oil-bearing seeds and oil-rich plants.

Hot and Cold Pressing: It is suitable for hot and cold pressing, so it really achieve using one machine to serve multi-purpose oil extraction.

Premium Quality: The wear parts, such as pressing rings, pressing bars and more, are made of premium quality carbon steel that is after tempering. So, the machine can perform for a longer time.

Higher Oil Yield: Automatic electric cabinet controls the oil pressing temperature for higher oil output compared to traditional counterparts.

Purer Oil: Since the vacuum filters can filters the crude oil automatically, so the oil is much pure.

Effortless and Convenient Operation: It requires one or two worker for normal operation, so it can also help to save the cost on laboring. And the automatic electric control improve the security of the whole machine.

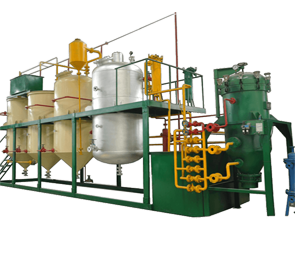

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

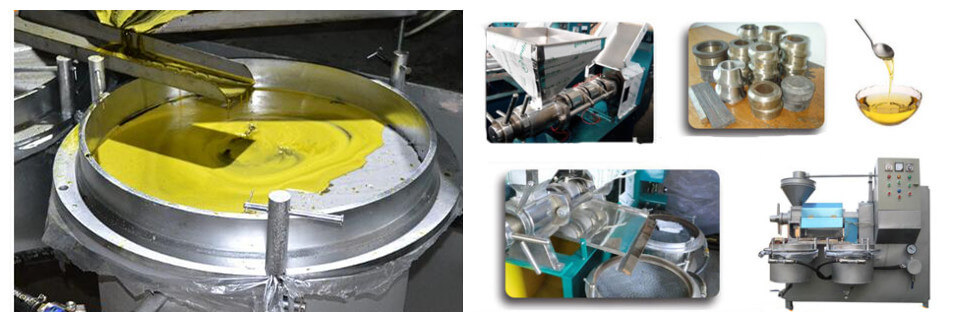

The three most common integrated filters are:

Plate-and-frame filters: Use layered filter cloths between metal plates to trap solids. They’re affordable, easy to clean, and effective for removing coarse meal particles (ideal for small-scale presses processing 50–200 kg/h soybeans).

Centrifugal filters: Spin crude oil at high speeds to separate solids via centrifugal force. They’re faster (handle 200–500 kg/h) and require less manual cleaning but cost more than plate-and-frame models.

Vacuum filters: Use suction to pull oil through a filter medium (e.g., diatomaceous earth). They’re best for producing clear, low-residue oil (critical if the oil is sold unrefined) but need regular filter medium replacement.

For soybeans— which produce crude oil with fine, protein-rich solids—centrifugal filters are often preferred for medium-scale use (balance of speed and clarity), while plate-and-frame filters work well for small, budget-friendly setups.

The integrated filter enhances quality in three key ways:

Minimizes oxidation: Crude soybean oil is exposed to air for less time (no manual transfer between press and filter), reducing oxidation (which causes rancidity and shortens shelf life).

Removes fine solids immediately: Soybean meal particles are tiny (10–50 microns) and can clog standalone filters or remain suspended in oil, making it cloudy. The integrated filter captures these solids before they settle, resulting in clearer oil with a longer shelf life.

Reduces contamination risk: Manual transfer of unfiltered oil (e.g., pouring into a separate filter) introduces dust, bacteria, or foreign debris. The closed-loop integrated system eliminates this risk, ensuring food safety compliance.

For unrefined soybean oil (a growing market for health-focused consumers), this clarity and purity are especially valuable—no additional filtering is needed before packaging.

Integrated machines are designed for small-to-medium throughput, with capacities ranging from 50 kg/h to 500 kg/h of soybeans (producing 9–90 liters of filtered oil per hour, based on 18–22% soybean oil content). This is lower than industrial standalone systems (which can handle 1,000+ kg/h) but more than sufficient for local processors, farm co-ops, or artisanal oil brands.

The tradeoff for lower capacity is efficiency: integrated machines have a smaller footprint (30–50% less space than separate press + filter setups) and require 1–2 operators (vs. 3–4 for standalone lines). For example, a 200 kg/h integrated machine can process 1.6 tons of soybeans in an 8-hour shift, producing ~320 liters of filtered oil—enough to supply local grocery stores or farmers’ markets.

While the machine combines pressing and filtering, soybeans still require pre-treatment to maximize yield and protect the integrated filter:

Cleaning: Remove stones, dirt, and broken seeds with a vibratory sieve—impurities can damage the screw press or clog the filter.

Dehulling: Strip soybean hulls (2–3% of weight) with a dehuller. Hulls are fibrous and can block filter pores, reducing filtration speed.

Flaking (optional but recommended): Crush soybeans into thin flakes (0.3–0.5 mm) with a roller mill. Flaking increases surface area for oil extraction and produces larger meal particles, which are easier for the integrated filter to capture.

Moisture adjustment: Dry or condition soybeans to 8–10% moisture. Wet soybeans (over 12% moisture) create sticky meal that clogs the filter; dry soybeans (under 6%) shatter, leaving fine particles that pass through the filter.

Yes, but you may need to adjust the filter or its settings to match the oilseed’s properties:

Sunflower/canola (high-oil, soft seeds): These produce crude oil with larger, less dense solids. For plate-and-frame filters, use a coarser filter cloth (100–150 mesh, vs. 200–250 mesh for soybeans) to speed up filtration. For centrifugal filters, reduce spin speed by 10–15% to avoid damaging the filter.

Cottonseed (low-oil, hard seeds): Cottonseed oil contains more gums, so add a small amount of filter aid (e.g., diatomaceous earth) to the integrated filter to improve gum removal.

Critical note: Never process seeds with high moisture (over 15%) or hard shells (e.g., peanuts in shells)—this will clog the filter and damage the press. Always clean the filter thoroughly between oilseeds to prevent cross-contamination of flavors.

For small operations (e.g., farm-based mills, local oil brands), the benefits are transformative:

Space savings: A single unit replaces two pieces of equipment (press + filter), fitting in garages, small warehouses, or farm outbuildings (typical footprint: 2–4 m² for 50–200 kg/h models).

Labor reduction: 1 operator can run the machine (vs. 2 for separate press + filter), cutting labor costs by 50%.

Faster time-to-market: Oil is ready for packaging immediately after pressing (no waiting for separate filtration), reducing lead times from days to hours.

Consistent quality: The closed-loop system ensures every batch of oil has the same clarity and purity, building customer trust for artisanal or local brands.

Lower upfront cost: An integrated machine costs 20–30% less than buying a standalone press and filter separately (e.g.,

Focus on these critical factors to ensure the machine meets your needs:

Filter compatibility with soybeans: Choose a machine with a centrifugal or plate-and-frame filter (avoid vacuum filters if you’re on a tight budget). Confirm the filter can handle fine soybean solids (look for 200–250 mesh cloths for plate-and-frame models).

Capacity match: Select a machine that aligns with your daily soybean input (e.g., 50 kg/h for 400 kg/day, 200 kg/h for 1.6 tons/day). Avoid overbuying—larger machines cost more to operate and maintain.

Material quality: Opt for stainless steel contact parts (press cage, filter chamber) to resist corrosion and meet food safety standards (cast iron is cheaper but prone to rust).

Warranty and support: Choose a brand that offers a 1–2 year warranty on the press and filter, plus local service (critical for repairing filters or replacing parts quickly).

Ease of use: Look for intuitive controls (e.g., digital pressure/temperature displays) and easy access to the filter (for cleaning)—this reduces training time for operators.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.