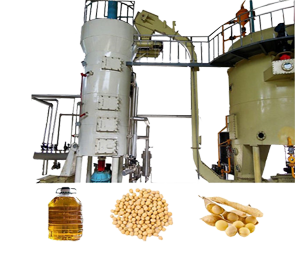

QIE Machinery is the leading oil processing machine manufacturer and supplier of soybean manufacturing oil machines. In order to meet more customers' needs, we provide one-stop service to help customers build up their own soybean oil processing plant for household or commercial uses, including equipment selection, manufacturing, installation and after-sale service, etc..

Processing Capacity: 1-30T/D

Processing Capacity: 1-30T/D Residual oil rate: 6-8%

Residual oil rate: 6-8%

all machine can be customized according to customers' needs.

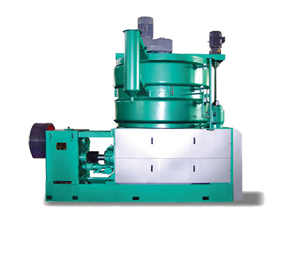

Soybean screw oil press machine is advanced oil processing machinery, characterized by its high oil yield with good quality, simple design and convenient operation. The Soybean screw oil press machine can be used for squeezing various raw materials, such as peanuts, rape seeds, cotton seeds, sunflower seeds and soy beans etc.

For the ones who are planning to start soybean oil processing business of mini or small scale, equipment selection and matching is the very important for the success of your business. Here we recommond you our small scale soybean oil extraction machine, capacity ranges from 1 ton/day to 30 ton/day.

Compared with the big capacity soybean oil mill plant, small scale soybean oil extraction machine needs less equipments. The most widely used machines in small scale soybean oil extraction process are: roasting machine, pressing machine, filtering machine and oil refining machine.

QIE Machinery is a professional small soybean oil mill plant manufacturer. We can provide soybean oil press machine, small scale soybean oil mill plant, soybean oil production line and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

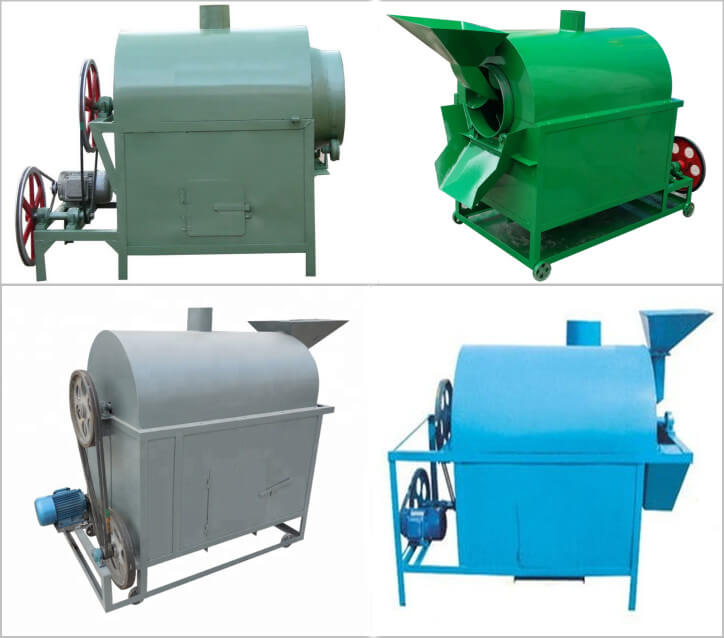

1.Roasting machine

This machine is to roast the soybean seed first before cooking,so you can get more oil out from next pressing plant

2.Pressing machine

The single screw oil press machine is an advanced expeller which is widely used in pressing oil from vegetable oil seeds. The oil separated from oil materials by the pressing power which comes from the change of chamber volume, drive from screw worm, resistance of curve teeth at press rings and extrusion friction between oil material. Depending on the intended use of the oil, our single screw oil press machine can be operated with either the cold or the hot press technique.The single screw oil press machine has the advanced design, convenient to operation, high output rate, strong compatibility and high efficiency. Suitable for medium and small sized oil extruding work shops or professional farmers.Also be used for pre-pressing submerging oil plant

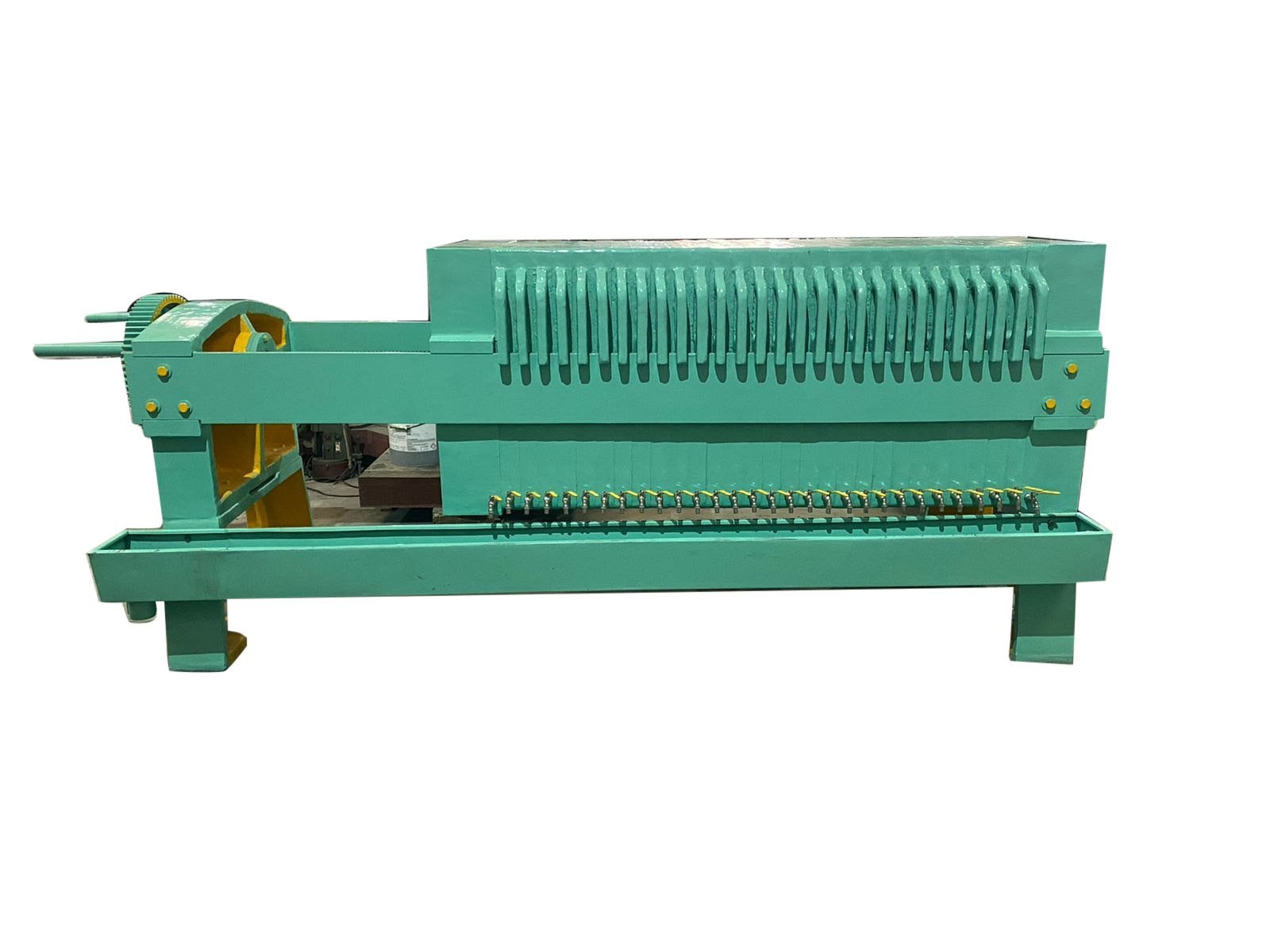

3.Soybean oil filter machine

This filter machine is to remove the impurities from crude soybean oil,so you can get clean soybean oil.Soybean oil filter machine is the major equipment iu soybean oil extraction machine.

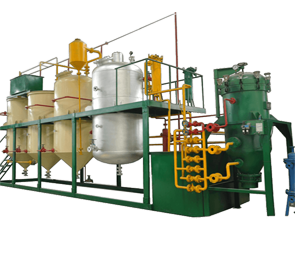

4.Soybean oil refinery machine

Soybean oil refinery plant is another important equipment in soybean oil extraction machine.The soybean oil refinery plant include four process:degummin g,deacidification,decolorization and deodorization.

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

In the way of oil pressing, screw type oil press produces high temperature through screw extrusion and extracts oil from oil. The hydraulic press uses the liquid as a medium to pressurize oil, to extract oil.

Soybean oil expeller machine: This is the most common type of machine used for soybean oil extraction. It uses mechanical pressing to extract oil from soybeans. Expeller machines are known for being cost-effective and efficient for small to medium-scale oil extraction.

To produce soybean oil, the soybeans are cracked, adjusted for moisture content, heated to between 60 and 88 °C (140 and 190 °F), rolled into flakes, and solvent-extracted with hexanes. The oil is then refined, blended for different applications, and sometimes hydrogenated.

Soybeans require specific pre-treatment to maximize yield and protect equipment:

Cleaning: Use vibratory sieves and air separators to remove stones, dirt, and broken seeds—impurities can damage the screw or cage and contaminate oil.

Dehulling: Remove hulls (2–3% of soybean weight) with friction or impact dehullers. Hulls are low in oil and high in fiber, which clogs the cage and reduces extraction efficiency.

Flaking (optional but recommended): Crush soybeans into thin flakes (0.3–0.5 mm thick) with roller mills. Flaking increases surface area by 50–100%, making oil easier to extract and boosting yield by 3–5%.

Drying/Conditioning: Adjust moisture to 8–10% using heated air. Wet soybeans (over 12% moisture) stick to the screw; dry soybeans (under 6%) shatter and leave oil trapped in fragments.

Screw soybean oil press machines are engineered for soybeans’ unique properties: low oil content (18–22%, vs. 40–50% for peanuts/sunflowers) and hard, dense kernels. Key design differences include:

A tapered screw with deeper flights: Gradually increases pressure over a longer compression zone (critical for extracting oil from low-oil seeds) instead of the steeper taper used for high-oil seeds.

A thicker, more durable cage: Resists wear from hard soybean kernels, with smaller perforations (1–2 mm) to prevent fine solids from mixing with oil.

Pre-heating integration: Many models include a built-in heating jacket around the cage to maintain temperatures of 60–80°C, softening soybeans to improve oil flow (unnecessary for softer, high-oil seeds).

These adaptations ensure efficient extraction from soybeans, whereas using a generic screw press would result in low yields (often <10%) and rapid equipment wear.

Yes, but it requires modifications (since soybean presses are optimized for low-oil, hard seeds):

High-oil seeds (peanuts, sunflowers):

Adjustment: Widen the discharge gap to reduce pressure (40–80 bars, vs. 80–120 for soybeans) to avoid overheating oil. Use a cage with larger perforations (2–3 mm) to prevent clogging from softer meal.

Note: Yield will be lower than a dedicated high-oil press (30–35% vs. 40–45% for sunflowers).

Medium-oil seeds (canola, rapeseed):

Adjustment: Reduce screw speed to 10–20 RPM (canola is softer than soybeans) and use a medium-pressure setting (60–90 bars).

Low-oil seeds (cottonseed):

Adjustment: Keep pressure high (80–110 bars) but add a pre-heating step (70–80°C) to soften cottonseed hulls.

Critical note: Never process seeds with hard shells (e.g., walnuts) or high moisture (over 15%)—this will damage the screw or cage.

Safety is critical due to the machine’s high pressure and moving parts:

Emergency stop button: Easily accessible (front of the machine) to halt operation during jams or operator risk.

Screw/cage guards: Metal enclosures around the rotating screw and cage to prevent clothing or hands from getting caught.

Overload protection: A sensor that shuts down the motor if the press is overfed (prevents motor burnout and screw damage).

Heat shields: Insulation around the heated cage to protect operators from burns (especially important for soybean presses, which run at 60–80°C).

Non-slip base: Heavy-duty rubber feet to stabilize the machine during high-vibration operation (prevents tipping).

Pressure relief valve: Releases excess pressure if the discharge port clogs, avoiding cage or screw damage.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.