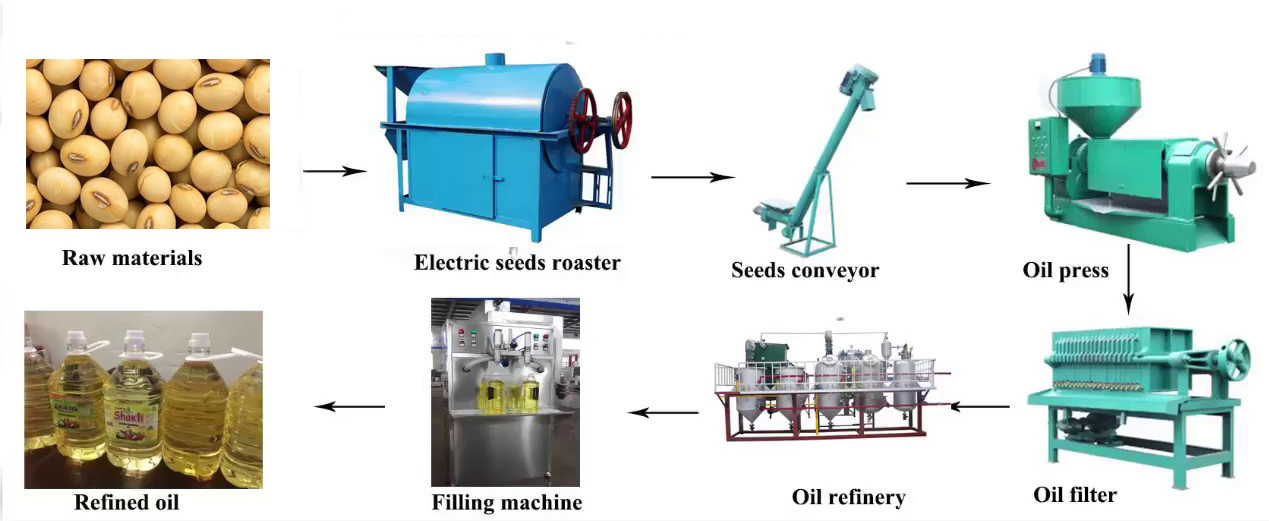

A Small soybean oil production line is designed for small to medium-scale edible oil mill plants, with capacities ranging from 1 TPD to 50 TPD, providing an efficient, cost-effective solution for producing high-quality edible oils from various oilseeds.This is an affordable and customizable soybean oil production solution that lets you meet local or small-market demands and provides a profitable way to turn oilseeds into marketable oil products.

Brand

QIE

Raw Material

Soybean

Capacity

1-50TPD

1-50TPD

Customized 1-50T/D Soybean Oil Production Line On Demand

Highly Intelligent Production In All Sections

Intelligent

In soybean oil production, the choice between mechanical pressing and solvent extraction depends on factors like plant capacity, oil yield requirements, production costs, and intended uses of the by-products (oilcake/meal). For small to medium production scales, when residual oil in the cake is acceptable or desirable, and when producing high-value, premium, or organic oils, we recommend using the mechanical soybean pressing method. The oil press machines have a capacity ranging from 1 to 50 tons per day (TPD), and they can extract about 70% of the oil in the soybean.

Refining is essential to improve the oil’s taste, smell, color, and stability, ensuring it meets market standards. Soybean oil refining plants can be tailored for first and second-grade oil production. The total refinery plant contains refining pot, decolorizing pot, deodorizing pot, steam generator, heat conduction furnace, etc.

Batch Oil Refinery Line 1-20TPD

Batch oil refinery is one of the main kinds of oil refinery methods, which is suitable for various vegetable and animal oils, such as soybean oil, peanuts oil, sunflower oil, rape seeds oil, cottonseeds oil, coconut oil, palm oil, niger seeds oil, rice bran oil, fish oil, seal oil, etc. It is suitable for small capacity, 1TPD to 20TPD, which contains Degumming, Neutralizing, Decolorization and Deodorization section. As a result, it can also be called small edible oil refinery unit.

Continuous Oil Refinery Plant >30TPD

Continuous Type Oil Refinery Plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This process line is bit expensive than batch oil refinery process but it provides superior quality refined oil along with automation system and low processing cost. It is also a large edible oil refinery unit.

Semi-Continuous Oil Refinery 10-50TPD

The semi-continuous oil refinery process design is based on batch type but higher than batch type. Semi-continuous oil refinery process needs less investment cost. The semi-continuous oil refinery capacity can be designed according to customer requirement. It's suitable for the middle type oil refinery plant from 10TPD to 50TPD. So it is also called middle scale oil refinery unit.

What capacity can QIE Machinery offer?

1TPD,2TPD, 3TPD, 5TPD,10TPD,15TPD, 20TPD, 30TPD (batch Design)

15TPD,20TPD.30TPD;(semi-Continuous Design)30TPD ,50TPD,100TPD,200TPD,400TPD (continuous Design)

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed soybean oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes soybean oil and soybean protein production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn More