A soybean oil processing plant extracts oil from soybeans through a multi-step process that includes cleaning, crushing, and flaking the beans before extracting the oil using either mechanical pressing or solvent extraction. The resulting crude oil is then refined to remove impurities, improving its color, odor, and suitability for consumption. Different plant configurations, from small-scale to large-scale, are available to meet varying production capacities, with processes and equipment tailored to the chosen oil extraction method.

Soybean → Cleaning → Crushing → Softening → Flaking → Cooking → Pressing → Filtering

1. Cleaning:

It uses magnetic separation, cleaning sieve and de-stoner to remove inorganic impurities, organic impurities and oil impurities inside soybeans.

2. Crushing:

Mechanical method can break soybean into small particles,thus protect the soybean oil pretreatment and pressing machine. Roller crusher is adopted to crush soybean for convenience of soybean flaking process.

3. Softening:

It can regulate moisture and temperature of soybean until softening, which can increase ductility of soybean. Soybean is low oil content oilseed with hard structure, thus powder control is important for further soybean oil extraction.

4. Flaking:

It cover pressing process from the granular formation into sheet. The purpose of soybean flaking is to destroy soybean tissue, create condition for steaming and roasting, make oil separation in soybean oil solvent extraction easily. Soybean flaking requires thin embryo, uniform surface, less powder, no oil reveal. Powder controls at 1mm mesh sieve material not exceed 10-15%, soybean flakes to 0.25-0.35mm.

5. Cooking:

It is used for adjusting the moisture in the materials. If the moisture content is too high, it is not suitable for pressing, so we need to reduce the moisture content to 7%-9%.

6. Pressing:

In soybean oil processing plant, there are two kinds of soybean oil pressing machine usually used. One is single screw soybean oil pressing machine, the other is large soybean oil pressing machine with auxiliary frying pan.

Before soybean enters into soybean oil pressing machine, further cleaning is necessary, which is in order to reduce impurity, and ensure that we can get high quality soybean oil. This is the brief introduction about soybean oil processing plant, any questions, you can send your enquiry to us.

Soybean oil solvent extraction plant adopts the most advanced solvent oil extraction method to extract crude soybean oil from soybean.

The first step is cleaning the soy seeds. Then, dry the seeds and dehull prior to oil extraction. You have to remove the soybean hulls because they absorb oil and give a lower yield. However, you can dehull by cracking the soybeans. Finally, separate the hulls and cracked soybeans mechanically. Additionally, you can use magnets to separate any iron particle from the soybeans.

The soybeans are also heated to about 75°C to coagulate the soy proteins to make the oil extraction easier. For extracting the oil cut the soybeans in flakes. Put them in a percolation extractors and immerse with a solvent, normally hexane.

Counterflow is used as extraction system because it gives the highest yield. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. Finally, separate the hexane from the soybean oil in evaporators. And recover the evaporated hexane and return to the extraction process. Now, the hexane free crude soybean oil is ready to go to the refineries.

We own rich experience of designing, manufacturing and installation of soybean oil extraction plant and guarantee high efficiency, high profit and reliable oil extraction process.

1. Adopting negative pressure evaporation can ensure excellent oil quality;

2. Extraction system is highly adaptable, and can adapt to different raw material ;

3. All equipments are provided with exhaust gas absorption systems with excellent absorption effect;

4. Full energy-saving design utilizes heat energy for many times and saves steam consumption;

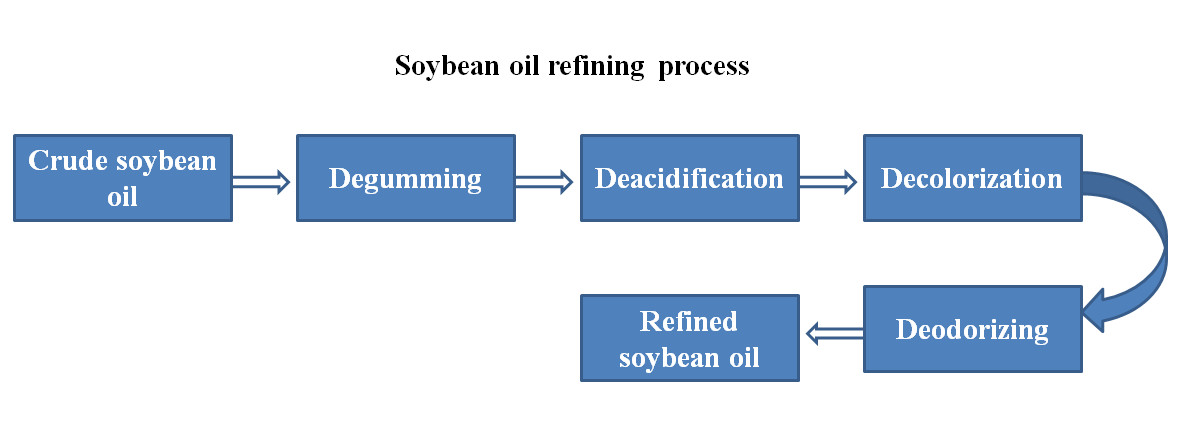

Crude soybean oil → degumming and deacidification→ decolorization →deodorization → refined soybean oil.

Crude soybean oil contains a large number of other ingredients that require further refining. In this section, continuous alkali refining shortens contact tome between oil and lye,which reduces oil saponification state,lowers refining consumption,and improves efficiency;negative pressure state avoids oxygen in the air from contacting with hot oil,thereby ensuring oil product quality ,inhibiting with hot oil,there by ensuring oil product quality,inhibiting acid value to rise again,and lowering peroxide value; physical refining section adopts new type continuous deacidiffication and deodorization craft, the actual production proves its most obvious advantages as following: strong deacidiffication ability ,excellent hot bleaching effect,high refining rate ,good oil quality etc.

For establishing the soybean oil production line plant, the primary requirement is the land. If you already have a space for the manufacturing operation, then it is fine. Otherwise, you can secure a space at any industrial zone on rent. Generally, a 2000 Sq Ft built up area is sufficient for a small-scale production. Some of the most important machines are

Solvent extraction plant

Boiler

Basically, a solvent extraction plant contains

Heat Exchangers

Dryer

Elevators

Seed Cleaner

Aspiration system

Cracker

Cooker

Flaker

Roll Grinding attachment

Hydraulic system

Conveyors

Rotary Air Lock

Feed Bin

Micro Level Indicators

Extractor

Rising Hoppers

Discharge Bin

Bulk Flow Conveyor

Rotary Air Lock

Toaster

Dust Catcher

Horizontal Tubular Condensor

Sealing Devic

Vapour Cooler,

Water Solvent Separator

Spent Water Desolventiser

Evaporator

Separator

Pre-Heater

Condensers

Oil Stripping Column

Heater

Oil Holding Tank

Vacuum Equipment

Final Vapour Absorber

Final Vertical Stripper

(1)High oil yield, obvious economic benefits;

(2)Lower oil residual rate in dried meal;

(3)Improving final oil & meal quality;

(4)Lower processing cost, higher productivity;

(5)High-level automatic control, labor-saving.

(6)Professional factory that based on national owned group.