Soybean is one of the most important oilseeds all over the world. Soybean is distributed mainly over America(32%), Brazil(28%), Argentina(21%), China(7%),India(4%), Paraguay (3%), Canada(1%) and other countries.

Approximately 85% of the world’s soybean crop is processed into soybean meal and soybean oil, the remainder processed in other ways or eaten whole. The soybean oil content is about 18%. Soybean is a kind of low oil content oilseed compared with other oilseeds as, peanut, sesame, canoal,etc. So usually we adopts soybean oil pretreatment and solvent extraction way to process soybean to get soybean oil. Compared with pressing way, pretreatment and solvent extraction way can reduce residue oil rate and increase oil productivity.

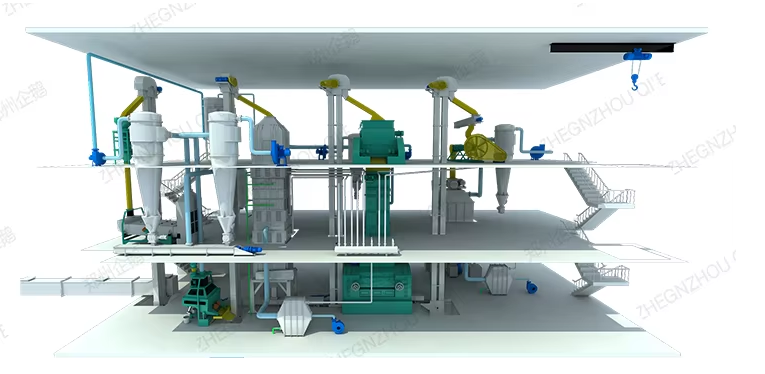

Cleaning: Remove most impurities from the material, such as stones, dirt, etc., to prepare for the next crushing process, improve crushing efficiency and extend machine life.

Crushing: After the crushing process, the material is broken into small pieces, which improves the efficiency of the material being pressed.

Softening process: Increase the moisture content and temperature of the material, and ultimately increase the final oil output of the material.

Flaking process: The material is pressed into pieces in this process to increase the amount of oil discharged from the material.

Extruder: The treated oil enters the squeegee from the hopper. Under the condition of high pressure, the embryo is continuously pushed inward by the screw press, and is pressed to finally produce oil.

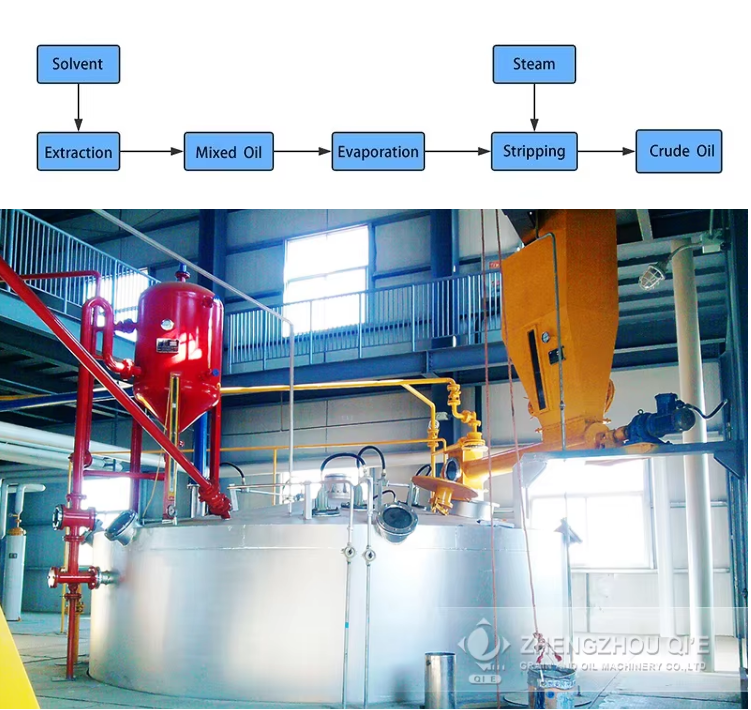

Extraction: It usually adopt an organic solvent that can dissolve the oil, through the material spray, soak, so that the oil will be extracted from the oil-bearing seeds.

DTDC: By continuously the multi-layered steam heating, the heat obtained by the solvent in the wet mash is vaporized, thereby separating the solvent from the wet meal, and removing the solvent remaining in the wet meal as much as possible.

Evaporation: The difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

Quality indicators of crude soybean oil

| Smell and flavour | Smell and flavor , typical of soybean oil , without foreign smell |

| Colour | Natural, brown with green tinge |

| Transparency | slightly turbid, might have a small sediment |

| Mass fraction of fatless substances,%, not more than | 0,20 |

| Mass fraction of humidity, % | 0,36 |

| Acid value, mg КОN/g | 4,00 |

| Peroxide number, ½ mol/kg, not more than | 5,00 |

| Mass fraction of substances which contain phosphates, %, not more than:in calculation to stearooleolecitine | 4,00 |

| Color quantity ( iodine value), not more than | 100 |

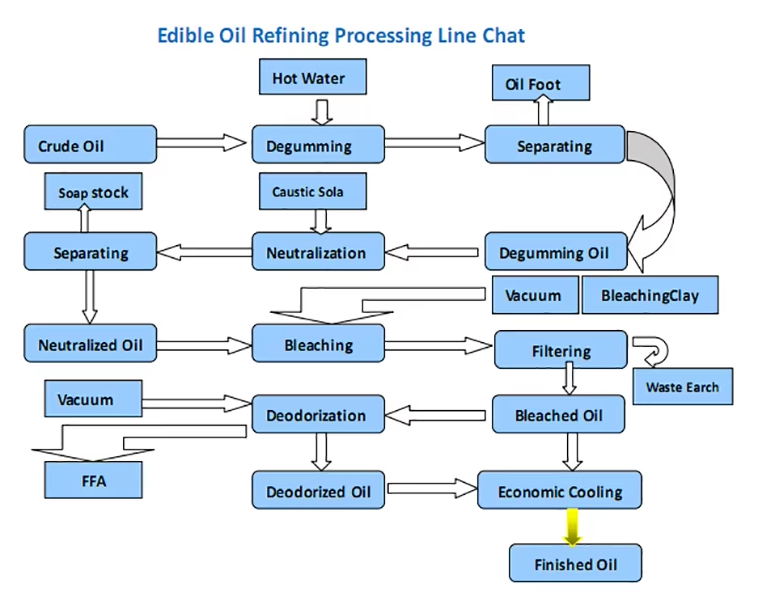

Terme général désignant une série de procédés visant à éliminer les impuretés solides, les acides gras libres, les phospholipides, les gommes, les cires, les pigments, les odeurs, etc. contenus dans les huiles végétales. Améliorer la valeur nutritionnelle des huiles alimentaires présente de grands avantages pour la santé humaine.

Deacidification and Degumming: This step is mainly to remove the excess acid in the grease.

Decolorization: The decolorization process greatly enhances the oxidation stability of the oil, and this process also has a great influence on the subsequent deodorization process of the oil.

Deodorization: Deodorization of oil and fat not only removes odor substances in oil, but also improves the safety of oils and fats.

Filteration: Miscella mixed by oil and clay from bleaching tower is pumped into decolorizing filter.

Dewaxing process: Bleached oil enter into crystallizing tank through heat exchanger and begin the cooling crystallization process.

Quality indicators of refined soybean oil

| Smell and flavour | No smell; depersonalized oil taste |

| Colour | Light yellow |

| Transparency | Transparent |

| Mass fraction of fatless substances,%, not more than | none |

| Mass fraction of humidity, % | 0,1 |

| Acid value, mg КОN/g | 0,3 |

| Peroxide number, ½ mol/kg, not more than | 5,00 |

| Mass fraction of substances which contain phosphates, %, not more than:in calculation to stearooleolecitine | 0,05 |

| Color quantity ( iodine value), not more than | 12 |

If you are interested in establish a soybean oil mill plant for making edbile oil and want to choose a strong oil mill manufacturer, you are in the right place then! QIE Machinery – a well known company with decades of experiences in soybean oil processing equipment and turnkey soybean oil mill business plan. There are different capacities available for the soybean Oil Mill Plant. We can provide and supply small scale as well as large scale soybean oil plants. The common capacity is of 10TPD, 30TPD,50TPD,100TPD,500TPD,2000TPD and so on. Any needs about soybean oil mill plant, welcome yo contact us!