A large scale soybean oil production plant involves several interconnected processes to efficiently extract oil from soybeans and produce high-quality refined soybean oil. The soybean oil production line includes the soybean pretreatment process, soybean pre-pressing process, soybean oil extracting process, and soybean crude oil refining process. With capacities ranging from 100tpd to 5,000tpd, our soybean oil production plants are perfect for meeting the demands of large-scale edible oil production requirements.

Brand

QIE

Raw Material

Soybean

Capacity

100-5000TPD

100-5000TPD

Customized Large Scale Soybean Oil Production Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

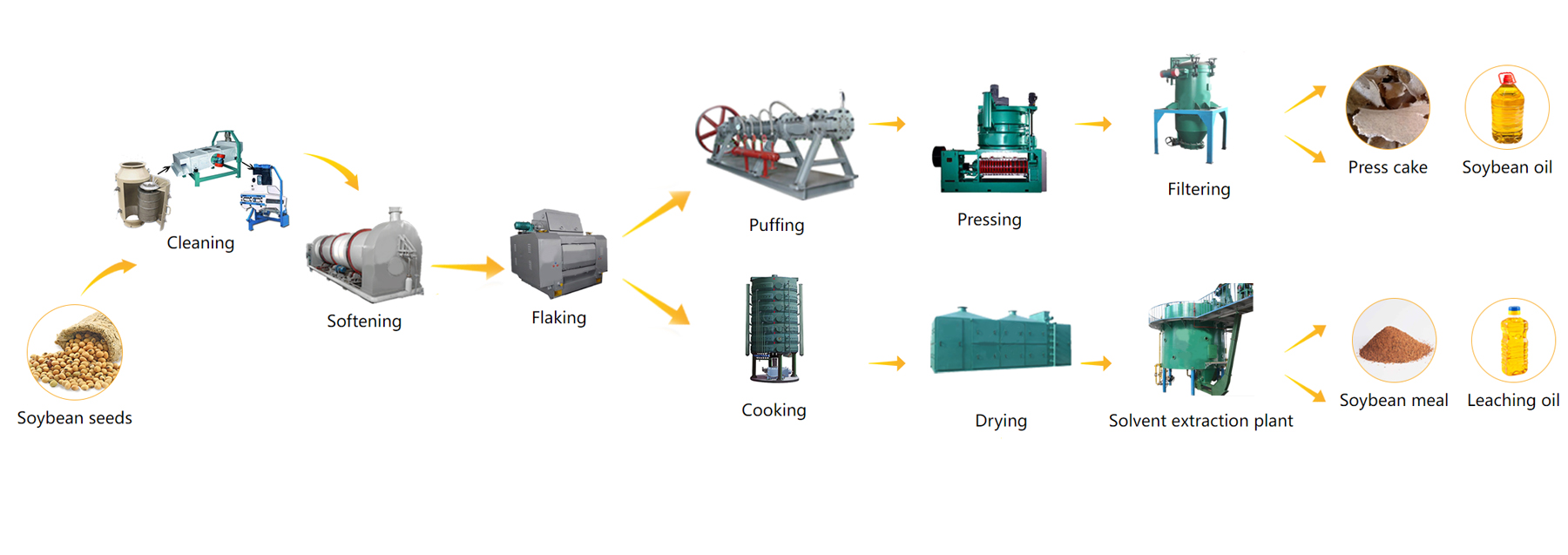

Before entering the workshop to make oil, soybeans need to go through cleaning, crushing, peeling, softening, flaking, cooking, Drying.

In soybean oil production, the choice between mechanical pressing and solvent extraction depends on factors like plant capacity, oil yield requirements, production costs, and intended uses of the by-products (oilcake/meal). The mechanical pressing method is usually a good choice for a soybean oil mill plant with a capacity under 100 TPD. For small to medium production scales, when residual oil in the cake is acceptable or desirable, and when producing high-value, premium, or organic oils, we recommend using the mechanical soybean pressing method. The oil press machines have a capacity ranging from 10 to 300 tons per day (TPD), and they can extract about 70% of the oil in the soybean.

Oil Extraction Section → DTDC Desolventizer Toaster Dryer Cooler → Oil Filtration Section → Evaporation and Separation Section → Solvent Condensation and Recovery System → Paraffin Absorption System → Water Solvent Separation and Recovery System → Automatic Control System

Customers can choose rotocel extractor or drag chain extractor based on their requirements. For different raw materials, grid trays clearance and grid trays arrangement will be properly adjusted to ensure that the oil residues in seed meal is minimum. In addition, liquids in seed meal will be completely drained off, which contributes to minimum solvent content. As a result, the burden imposed on desolventizing device in sequential process will be greatly alleviated, which further reduces steam consumption.

The machine consists of pre-desolventizing layer, heat exchange layer, desolventizing layer, heat recovery layer, drying layer and cooling layer. Materials levels at each layer can be automatically controlled. Full utilization of secondary steam reduces steam consumption. Mixed steam will be used to heat miscella after meal foam removal, which further saves energy. The process features thorough desolventizing, light yellow meal, complete passivation of antinutritional factors, short time required for high temperature desolventizing and low loss of meal NSI.

The process is designed to filter out solid impurities prior to miscella evaporation. Devices used include high pressure delivery pump, centrifugal separator and filter with slagging function. Optimum filtration effect can be achieved by combination of centrifugal separation precise filtration. Since the filter is able to remove slags automatically, no manual operation is required.

Devices used in the process contains evaporator, disc stripping tower, flash separator, heat exchanger and vacuum unit. Under a vacuum and negative pressure condition, solvent in the miscella will be evaporated and separated by rising film evaporation and direct stripping. After thorough desolvation, bright color leached oil will be obtained. To ensure system stability and reliability, an automatic PLC control system is adopted for control of evaporating temperature and vacuum level. Both mixed steam and power steam for vacuum pump will be sufficiently used for evaporation. Heat transfer and mass transfer between cool and hot medium furthers reduces steam consumption. In addition, lipid oxidation can be prevented as well.

The system mainly consists of condenser and circulating cool water system. Under the vacuum condition, condensable solvent steam is condensed into liquids for cyclic utilization through dividing-wall heat transfer. Multiple-pass structure of the condenser and proper settings of flow rate and speed of circulating water will greatly improve efficiency of condensation and separation and largely reduces investment capital and operating cost. In addition, tube plates, baffle plates and heat exchange tubes are all made of stainless steel, which facilities cleaning and withstands corrosion. Moreover, great condensation effect and long service life can be fully ensured.

The system consists of Paraffin absorption column,Paraffin desorption column,hear exchanger,storage tank, punp,Exhaust gas blower and so on. It is able to recycle more than 98 percent solvent in the exhaust gas, which reduces solvent loss and protects environment at the same time. The system makes use of food-grade liquid paraffin to adsorb solvent gas mixed in exhaust gas. The solvent steam will be distilled and separated with the help of superheated steam. Then the solvent steam obtained will be recycled through condensation. To ensure stable absorption efficiency and system reliability, automatic control devices are applied to control important parameters such as flow rate, temperature and pressure.

The system consists of solvent-water separator, boiling tank,and fresh solvent pump. It separates water from solvent based on the principle that water repels solvent and two liquid layers will be formed in their mixture. To ensure stability and reliability of the system, automatic control devices are applied to control important parameters such as flow rate, temperature and material level.

In our production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today`s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network. We utilize high-speed and large-capacity S7-400 series PLC at the control system, large-screen LCD at the operation station, WINCC 7.0 industrial control software as monitoring software and PROFIBUS filed bus network for communication.

We can offer turnkey soybean oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

Some impurity, such as Phospholipid, gum, and protein, can be dissolved into oil when there is no water, but once there is water in oil, these impurities can be dissolved into water. So, in degumming section of soybean oil refinery plant, we use the hot water to wash crude oil for two-three times to remove these impurities.

Neutralizing/Neutralization Proces

The crude oil is fed into the neutralizer and mixed with small amounts of degumming agent such as phosphoric acid to help remove gums.Free fatty acids are removed from the oil by adding caustic soda and heating it at 60˚ then stirring the mixture. Heating forms soap base, which is then precipitated and collected, and washed with water to remove alkaline particles.

Decolorizing Process

The neutralized oil requires bleaching machine to get rid of colors. This is done by adding the oil in a bleacher machine whereby it is heated to remove any moisture it might have and then mixed with earth bleach and activated carbon. These two properties absorb any colors after which the oil is passed through a filter to separate oil from earth bleach and carbon. The result is golden light oil.

Deodorizing Process

The golden light oil has unpleasant odors which result from materials such as aldehydes, ketones, tocopherols and phenols among other odiferous elements. Deodorizing process of soybean oil refinery plant helps remove these odors by adding the oil in the deodorizer and heating it above at very high temperature and under very high vacuum. This deodorizing process helps get rid of all odors.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed soybean oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes soybean oil and soybean protein production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn MoreThe plant’s infrastructure is a complex ecosystem of interconnected systems:

Soybean receiving & storage: Rail/truck unloading stations, weighbridges, and climate-controlled silos (with moisture/ temperature sensors) to store 1–2 months of soybean supply (100,000+ tons).

Pre-treatment line: Industrial cleaning systems (magnetic separators, air classifiers), dehullers, flaking mills, and conditioning towers—capable of handling 20–200 tons of soybeans per hour.

Pressing line: 4–10 large scale screw presses (1,000–5,000 kg/h each) with integrated cooling and filtration to extract crude oil.

Refining line: Continuous degumming, neutralization, bleaching, and deodorization units (100–1,000 liters/h each), plus winterization systems for cold-resistant oil.

Byproduct handling: Meal cooling/grinding lines, hull drying systems (for biomass), and soapstock processing units (for soap manufacturing).

Packaging & logistics: Bulk oil tanks (10,000–100,000 liter capacity) with port/rail loading arms, and bottled oil lines (5–20 liter containers) for retail.

Support systems: Biomass boilers, wastewater treatment plants (WWTP), laboratories, and administrative offices—often occupying 50–200 acres of land.

With capacities ranging from 10tpd to 5,000tpd, our soybean oil production plants are perfect for meeting the demands of large-scale edible oil production requirements. We can supply complete soybean oil production lines with capacities of up to 5,000 tons per day.

The pretreated soybean flakes are sent to the soybean solvent extraction plant. The soybean oil extraction plant uses a kind of solvent (normal hexane) to absorb the oil from the soybean, and then the machines separate the solvent from soybean crude oil. The solvent can be recycled, and the soybean crude oil is refined by an oil refinery plant.

The process includes:

Cleaning & Preparation (removing impurities)

Crushing (breaking soybeans into flakes)

Extraction (using solvents or mechanical pressing)

Degumming (removing phospholipids)

Refining (neutralization, bleaching, deodorization)

Fractionation (optional for specialty oils)