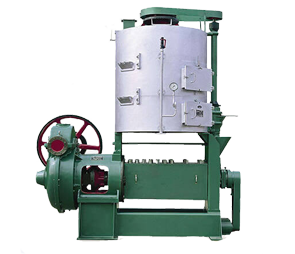

ZY20(202-3) pre-pressing machine, which is redesigned on the basis of the 202 pre-pressing machine, has advantages of the reasonable transmission gear, compact structure, and small footprint. And the machine has achieved improvements in the aspects of steaming, dehydrating, uniform feeding, mechanical wringing, and squeezing cage loading and unloading.

Processing Capacity: 40-50 T/D

Processing Capacity: 40-50 T/D Residual Oil Rate: 14~18%

Residual Oil Rate: 14~18%

all machine can be customized according to customers' needs.

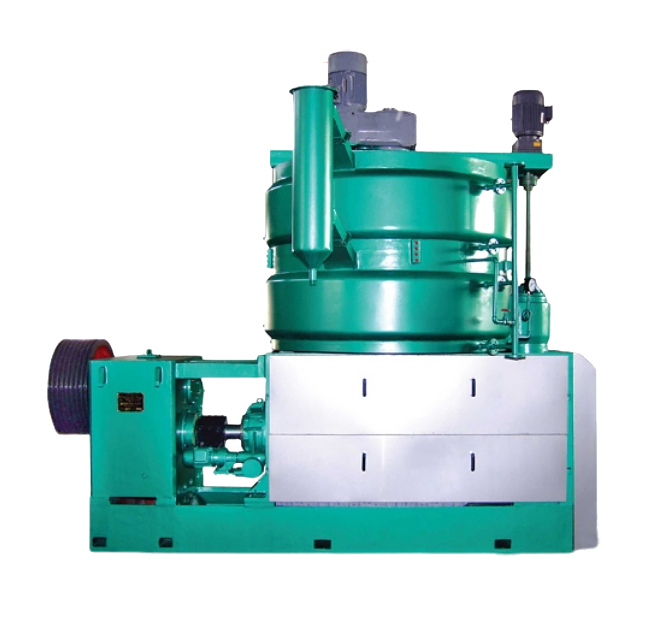

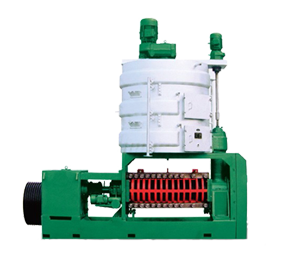

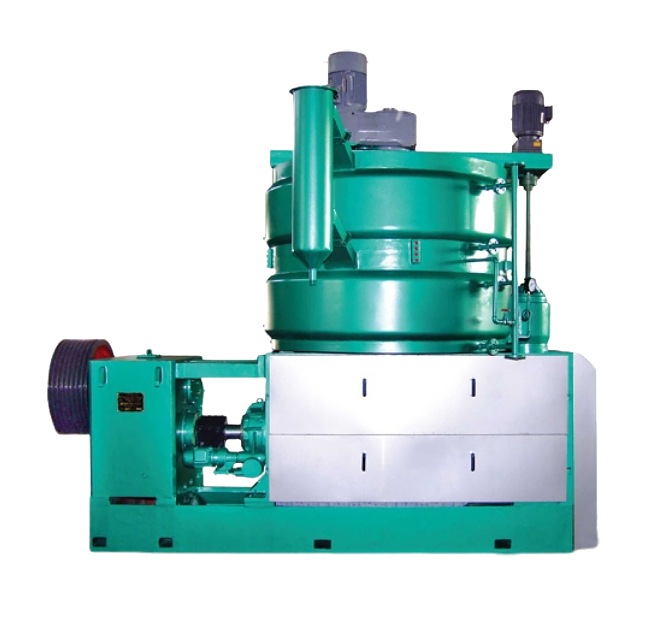

ZY20(202-3) screw oil pre-press is a continuous oil expeller which is suitable for preliminaly pressing- solvent extracting press or twice pressing process in small and medium- sized oil plant, and used to handle with oil seeds such as rapeseed, peanut, sunflower, and cottonseed kernels. It has the following advantages: high processing ability;low power consumption; low operation expense; defatted cake being loose but not crushed, easy to sovent penetration; low residual oil rate.

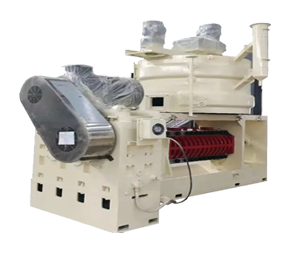

ZY24(202-3) Screw Oil Pre-Press Screw Oil Press pressing machine's characteristics have suited to pre-press soybean oil. Under normal pre-pressing conditions, its features are:

1. The machine is made up of stainless steel. The use of high-quality steel carburizing heat treatment can greatly extend the service life of the equipment.

2. Large capacity, small workshop area, low power consumption, less operation management and maintenance work.

3. The structure of the pre-squeezed cake is loosened but not crushed, which is favorable for the solvent to permeate when leaching; And the oil content and water content of the squeezed cake are suitable for solvent extraction.

4. The quality of squeezed oil is better than that of squeezing or leaching once.

QIE Machinery is a professional soybean oil mill plant machine manufacturer. We can provide soybean oil expeller machine, large scale soybean oil mill plant, automatic soybean oil mill plant and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

| Model | ZY24(202-3) |

| Processing Capacity | 40~50 T/D |

| Residual Oil Rate of Cake | 10~18% |

| Power Matching | 30KW |

| Overall Dimensions(L×W×H) | 2900×1850×3640mm |

| Weight | 5500(kg) |

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

ZY24(202-3) type pre-squeezing machine is made up of the following main components: steamer, feeding mechanism, squeezing cage, squeezing screw shaft (including the cake adjustment mechanism) and transmission.

1. SteamerThis equipment is a vertical three-tier steamer, similar to a typical vertical auxiliary steamer, mounted on a bracket of the frame. Its drive motor is included in the total driveline and steaming can adjust the temperature and moisture of the raw material before it enters the press chamber so that it reaches the requirement of pressing.

2. Feeding MechanismThe working part of the feeding mechanism is between the discharge port of the steamer and the feeding end of the squeezing shaft. It consists of the squeezing shaft with screw blades at the lower end and the falling cylinder. The entrance of the cylinder has a rotary control valve for controlling the falling flow. There is a hopper under the valve, from which the falling conditions can be observed and the material could be taken out as samples during pressing.

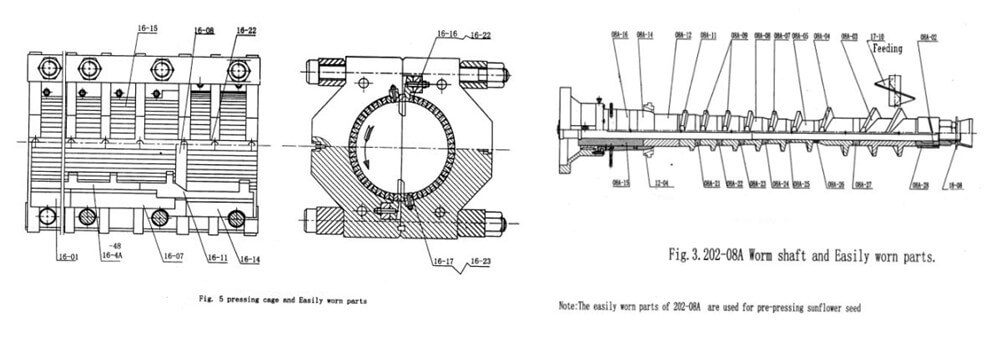

3. Squeezing Cage and Squeezing Screw Shaft

The squeezing cage and squeezing screw shaft are the main components of this equipment. Firstly, the material is pressed down by the feeding mechanism and continuously enters into the space between the squeezing cage & the squeezing screw shaft (called squeezing chamber). Due to the rotation of the squeezing screw shaft and the squeezing chamber gradually reduce the gap, the material is under intense pressure and most of which is pressed out of oil, next, the oil would flow out through the gap of squeeze cage.

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

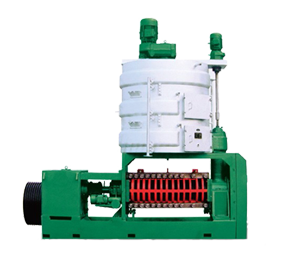

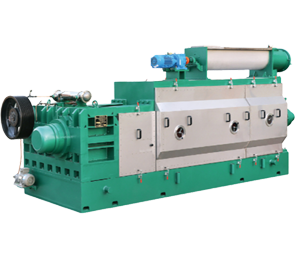

The ZX series operates on the principle of mechanical pressing. It has a screw shaft within a press cage. As the screw shaft rotates, it conveys the pre - treated oilseeds through the press cage. The pitch of the screw gradually decreases, and the space between the screw and the cage bars also narrows. This causes the oilseeds to be compressed. The pressure generated forces the oil out of the seeds, which then seeps through the gaps in the cage bars. Before pressing, many models in the ZX series are equipped with a steaming wok. This allows for the adjustment of the moisture and temperature of the oilseed material embryo. For example, the appropriate moisture content for most seeds is around 8 - 12%, and the temperature can be adjusted to 60 - 80°C, which softens the seeds and improves oil extraction efficiency. The process from feeding the seeds, steaming and cooking them (if applicable), to discharging the oil and forming the cake is continuous and automatic in most ZX series models.

Screw oil presses are highly versatile and can process most oil-rich seeds, including:

The machine’s performance depends on seed preparation (e.g., dehulling for sunflower seeds, moisture adjustment for soybeans) and press settings (e.g., screw speed, cage tightness). Some models are optimized for specific seeds (e.g., cold-press screws for sesame), but most are adjustable for multi-seed use.

Oil yield depends on the seed type, preparation, and machine quality, but typical ranges are:

Screw presses generally achieve 70–90% of the seed’s total oil content. For example, soybeans with 20% oil content yield 14–18% oil (residual oil in the cake is 2–6%). Hot-pressing often increases yield by 2–5% compared to cold-pressing due to better oil flow at higher temperatures.

Seed preparation: Proper cleaning (removing stones/dirt) prevents equipment damage; conditioning (moisture 8–12%, temperature 60–80°C) softens seeds for better oil release.

Screw design: The screw’s pitch, diameter, and compression ratio (ratio of initial to final volume) determine pressure. A steeper compression ratio (e.g., 1:8) increases yield but requires more power.

Operating parameters: Screw speed (50–200 rpm) affects residence time—slower speeds allow more thorough pressing but reduce throughput.

Maintenance: Worn screws or clogged cage slots reduce pressure and yield; regular cleaning and lubrication prevent inefficiencies.

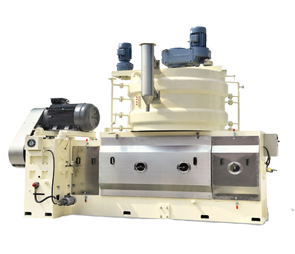

Large-scale oil presses are engineered for efficiency, automation, and durability, with key differences including:

Power consumption scales with capacity, but large-scale presses typically require 50–500 kW of electrical power, with additional energy for auxiliary systems:

Large-scale presses are part of integrated systems that include:

Integration is managed via PLCs, which synchronize all stages to maintain consistent flow—e.g., adjusting feed rate if the press slows down to prevent bottlenecks.

Consistency control: Maintaining uniform seed quality (moisture, purity) across large batches is critical—variations can reduce yield by 2–5%.

Energy costs: Fluctuations in electricity or fuel prices impact profitability; many plants use on-site renewable energy (solar, biomass) to mitigate this.

Regulatory compliance: Meeting food safety standards (e.g., EU REACH, FDA) for oil purity and worker safety (OSHA, ISO 45001) requires ongoing investment in testing and training.

Downtime risk: A single breakdown can halt the entire line, so plants often have backup presses or redundant systems for critical components.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.