Soybean oil is rich in nutritional components, containing unsaturated fatty acids such as oleic acid and linoleic acid, as well as vitamins A, B1, B2, carotene, vitamin E, calcium, phosphorus, iron, lecithin, sterols, etc. It is considered a heart-healthy oil because the polyunsaturated fats in it can help lower bad cholesterol levels (LDL), reducing the risk of heart disease.

According to different processing methods, soybean oil can be divided into cold-pressed soybean oil and hot-pressed soybean oil. In the production process, manufacturers generally use the solvent extraction method to obtain most of the oil from soybeans. The finished soybean oil on the market is mostly produced by the solvent extraction method.

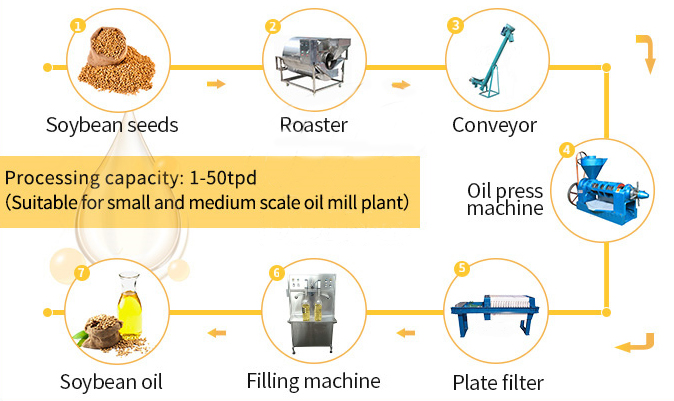

Small scale soybean oil processing plant are compact, cost-effective production units designed to extract high-quality edible soybean oil from soybeans, primarily catering to local markets, small businesses, or rural communities. Unlike large industrial facilities that require massive capital investment and extensive land, these small-scale plants balance efficiency, simplicity, and affordability—making them an ideal choice for entrepreneurs looking to enter the edible oil industry or meet regional demand for fresh, traceable soybean oil.(Read more: How to choose the right soybean oil refinery machine?)

Soybean Cleaning

Raw soybeans often contain impurities like stones, dust, straw, or broken kernels, which can damage equipment and affect oil quality. The plant uses vibrating sieves and magnetic separators to remove these contaminants. Vibrating sieves filter out large impurities (e.g., stones, straw) based on particle size, while magnetic separators capture metal fragments—critical for protecting downstream machinery like crushers.

Soybean Conditioning (Optional but Recommended)

To optimize oil extraction efficiency, cleaned soybeans are gently heated and adjusted for moisture content (typically to 8–10%). This “conditioning” process softens the soybean kernels, loosens the structure of oil cells, and prevents excessive powdering during crushing. Small plants often use low-temperature hot air dryers for this step, which are energy-efficient and easy to operate.

Crushing & Flaking

Conditioned soybeans are first crushed into small pieces (3–5 mm) using a roller crusher to break the outer hull. Then, they are pressed into thin flakes (0.3–0.5 mm thick) with a flaking roller. Flaking increases the surface area of the soybean material, allowing oil to be released more easily in subsequent extraction steps—this is a key factor in improving oil yield for small plants.

Oil Extraction

Small-scale plants typically use one of two extraction methods, depending on budget and output needs:

Mechanical Pressing (Cold/Hot Press): The most common method for small operations. Flaked soybeans are fed into a screw press, where high pressure (and optional low heat for hot pressing) squeezes out crude soybean oil. Cold pressing (below 60°C) preserves more nutrients (e.g., vitamin E, unsaturated fatty acids) and produces oil with a milder flavor, while hot pressing (60–100°C) yields a higher oil rate (up to 18–20% from soybeans).

Solvent Extraction (Small-Batch): For plants with slightly larger output (500–1,000 kg of soybeans per day), a mini solvent extraction unit may be used. Food-grade solvents (e.g., hexane) dissolve the oil from soybean flakes, and the solvent is then recovered via distillation (and recycled) to leave crude oil. This method has a higher yield (20–22%) but requires stricter safety controls for solvent handling.

Crude Oil Refining (Optional)

Crude soybean oil from extraction contains impurities like free fatty acids, phospholipids, pigments, and odors. Small plants can add a mini refining line (including degumming, neutralization, decolorization, and deodorization) to produce refined, clear soybean oil that meets edible standards. For local markets that prefer “natural” oil, some plants skip refining and sell crude oil (often labeled as “unrefined” or “virgin” soybean oil).

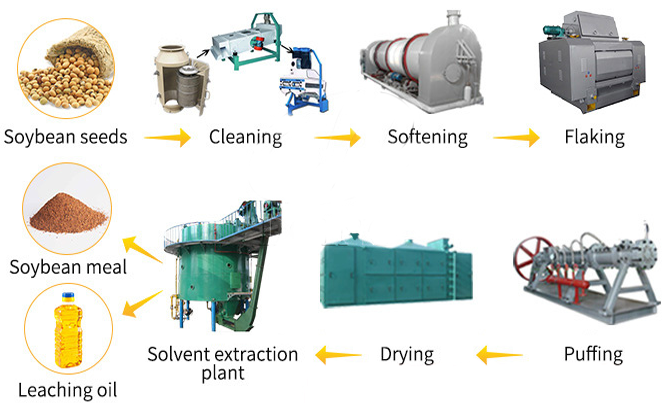

Large scale soybean oil processing plant are industrial-grade production facilities engineered for high-volume, continuous extraction and refining of soybean oil, primarily serving national or international markets, large food manufacturers, and bulk oil distributors. Unlike small-scale plants that prioritize flexibility and low investment, these large facilities are designed for maximum efficiency, consistent quality, and economies of scale—making them the backbone of the global edible oil supply chain, capable of processing thousands of tons of soybeans daily to meet massive consumer and industrial demand.(Related post: Establish A Small Scale Soybean Oil Production Line >>)

Soybean Pre-Cleaning

Large plants receive soybeans in bulk via trucks, trains, or ships, with storage silos capable of holding 10,000–100,000+ tons of raw material. Upon arrival, soybeans first pass through bulk pre-cleaning systems—including heavy-duty vibrating screens, air classifiers, and magnetic separators—to remove large impurities (stones, sticks), light debris (dust, chaff), and metal contaminants. This step is critical for protecting high-speed downstream equipment and preventing quality defects in the final oil.

Soybean Conditioning & Dehulling

To optimize oil yield and reduce hull content (which affects oil quality and meal value), cleaned soybeans undergo precise conditioning. Continuous steam conditioning towers adjust moisture content to 9–11% and temperature to 40–50°C, softening the kernels while preserving oil quality. Next, mechanical dehullers separate soybean hulls (via aspiration and sieving)—the hulls are often recycled as biomass fuel or used in animal feed. Dehulled soybeans (called “meats”) move to the next stage with minimal hull residue (<2%).

Crushing, Flaking & Cooking

Dehulled soybeans are first crushed into 2–4 mm particles using high-speed roller crushers (capable of processing 50–200 tons per hour). They are then pressed into thin, uniform flakes (0.2–0.3 mm thick) by multi-roll flaking machines—this maximizes surface area for efficient oil extraction, a key factor in achieving high yields at scale. The flakes are then fed into continuous cooking kettles or steam-heated cookers, where they are heated to 80–100°C to denature proteins, inactivate enzymes (e.g., lipoxygenase, which causes off-flavors), and further loosen oil cells.

Large-Scale Solvent Extraction

Nearly all large-scale plants use continuous solvent extraction (the most efficient method for high-volume production). Flaked, cooked soybeans are fed into a countercurrent extractor (e.g., loop-type or basket-type extractors), where food-grade hexane (or other approved solvents) circulates in a closed loop. The solvent dissolves the soybean oil, forming a “miscella” (oil-solvent mixture), while the remaining solid material (soybean meal) is discharged and sent for solvent recovery. The miscella is then pumped to distillation columns, where hexane is vaporized (and condensed for reuse, with a recovery rate of >99.5%) to leave crude soybean oil. This process achieves an oil yield of 20–23%, with the remaining soybean meal (high in protein) processed into animal feed pellets.

Crude Oil Refining

Crude soybean oil from extraction contains impurities (free fatty acids, phospholipids, pigments, waxes, and odors) that must be removed to meet global food standards (e.g., FDA, EU Food Safety Authority). Large plants use continuous refining lines with four key stages:

Degumming: Phospholipids are removed by adding water or acid, forming a gum precipitate that is separated via centrifuges.

Neutralization: Free fatty acids are neutralized with sodium hydroxide (caustic soda), producing soapstock (recycled for biodiesel or fatty acids) that is removed via centrifugation.

Decolorization: The oil is treated with activated clay or carbon in vacuum decolorization towers to remove pigments (e.g., carotenoids, chlorophyll), resulting in a pale yellow color.

Deodorization: In high-vacuum deodorization columns, the oil is heated to 220–250°C with steam injection to strip volatile compounds (causing off-odors), producing refined, odorless soybean oil.

Oil Blending, Packaging & Storage

Refined soybean oil is often blended with other oils (e.g., canola oil, sunflower oil) in automated blending tanks to adjust fatty acid profiles or improve stability for specific uses (e.g., frying, salad dressings). The finished oil is then packaged via high-speed filling lines into bottles (500 mL–5 L), drums (200 L), or bulk tankers. For long-term storage, large plants use insulated, temperature-controlled storage tanks (capacity 500–10,000+ tons) to prevent oxidation and maintain quality.

Setting up a full soybean oil mill plant requires balancing scale with market demand, investing in quality equipment, and adhering to regulatory and sustainability standards. Small plants excel at local, niche markets with low upfront costs, while large plants dominate global supply chains via efficiency and economies of scale. Success hinges on thorough pre-planning, stable sourcing, and consistent quality control.