Soybean oil is one of the most widely consumed vegetable oils in the world. It is extracted from the seeds of the soybean plants through a series of extraction methods. There are usually two main methods: soybean oil extraction, one is physical pressing method and the other is chemical solvent extraction method. Below, I will introduce them to you one by one.

The soybean oil solvent extraction plant is part of vegetable oil processing plant which is designed to extract oil directly from oil seed containing less than 20% oil like soybean flaking or it extracts oils from prepressed or fully pressed cake of seeds containing more than 20% oil like sunflower, peanuts, cotton seed, palm kernel, canola, copra, castor and variety of other materials.

Solvent extraction is the most commonly used industrial method of soybean oil extraction. It involves using organic solvents to dissolve and extract the oil from soybean seeds. This method ensures high oil yields but requires careful monitoring to minimize solvent residue in the final product.

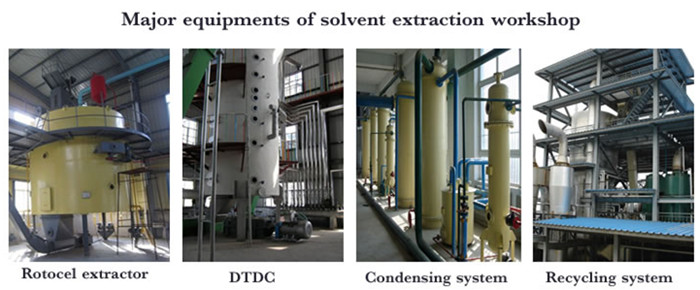

The solvent extraction process of soybean oil contains four section: oil extraction, desolventization, mixed oil stripping and steaming, solvent recycling.

Oil extraction section: Use solvent (n-hexane) to extract the oil from soybeans, and then get two kinds of products. One is wet meal with solvent, the other is mixed oil (solvent and soybean oil).

Desolventization section (DTDC System): The main equipment, desolventizing-toasting-drying-cooling tower will separate the solvent from wet meal. Then the meal can be packed to sell as animal feed.

Mixed oil stripping and steaming section: Through 1st evaporator, 2nd evaporator and stripping tower, the mixed oil can be separated into two parts. Solvent will be sent into the last section to recycle.

Solvent recycling section: Through cooling, recycle the solvent into solvent turnover tank.

Solvent pumps:continuously spray solvent to the rotary-type extractor

Rotocel extractor:Spray and soak the pre-pressed cake with solvent so that oil fats can be dissolved in solvent(form miscella). After processing, you can get wet meal and micella (mixed oil).

DTDC:Used to separate the solvent from the wet meal.

Miscella tank 1st: pump the miscella (oil with solvent) in to the miscella 1st , and then add 10% saline water to it. The phospholipid and impurities in the miscella will react with the saline water,at last the reactant precipitate, reaching the goal of purifying.

Miscella tank 2nd: the purified miscella will be pumped into it.

Miscella stripping:it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for recycling.

Condensers:used to cooling the solvent gas separated from the wet meal and miscella for recycling.

Solvent extraction uses a chemical solvent, typically hexane, to dissolve and extract oil from soybean flakes, maximizing oil yield. This method is generally favored for large-scale soybean oil production, high-yield requirements, efficient cost-per-ton output, and when soybean oil mill plant produce high-protein soybean meal for animal feed.

Large-Scale Soybean Oil Production:

Capacity Range: Best for oil mill plants with capacities greater than 50 TPD, often from 100 to 5,000 TPD. Large-scale soybean oil solvent extraction is highly efficient and cost-effective for high-throughput production, ideal for meeting commercial demand.

Low Oil Content Soybeans:

Solvent extraction is effective for soybeans with relatively lower oil content or if maximum oil recovery is required. It can extract 99% or more of the oil content, leaving minimal residual oil in the meal.

High Yield Soybean Oil Requirements:

For maximum profitability, solvent extraction is the preferred method since it allows almost complete oil recovery. This method also enables further processing of the residual meal as a high-protein feed product, increasing overall product value.

Economic Feasibility for High Capacity:

Although soybean oil solvent extraction has higher initial setup costs, it is economical in large-scale soybean oil production where the high yield justifies the investment. Lower residual oil in the meal and solvent recycling reduce long-term operational costs.

Meal Quality for Animal Feed:

Solvent extraction leaves only trace amounts of oil in the meal, which enhances the protein concentration, making it a high-quality feed. This high-protein, low-oil meal is widely used in the animal feed industry, especially for poultry and livestock.

Being incredibly versatile, soybean oil finds its uses in several cooking methods, like baking, roasting, and frying.

Let’s see some of the fantastic benefits that this edible oil offers.

Versatile and Easy to use

Owing to a high smoking point, soybean oil can easily replace any other vegetable oil in your kitchen. It suits high-heat cooking methods like sauteing, roasting, or frying.

You can pair it with a dash of pepper and salt, and vinegar for a quick salad dressing. Soybean oil’s neutral, mild taste makes it fit for any soybean oil recipe.

Improves skin health

Soybean oil contains vitamin E, which is known to treat many skin diseases and provide protection against skin damage.

Researchers have proven the effectiveness of this edible oil in protecting skin inflammation resulting from ultraviolet radiation. For this good reason, it has taken its place in various skin care products.

Promotes bone health

Including just one tablespoon of soybean oil in your meal can fulfill around 20% of the recommended daily requirement of vitamin K in your body. This is because only 15 mL contains approximately 25 mcg of vitamin K.

The vitamin not only plays a crucial role in regulating bone metabolism but is also known for its effectiveness in blood clotting.

Lowers risk of heart disease

Soybean oil is rich in omega-3 fatty acids known to protect against heart disease, besides helping in reducing inflammation.

Apart from this, edible oil mainly contains polyunsaturated fatty acids, considered heart-healthy fats, and helps lower the risk of heart disease. So, including soybean oil in your diet can help keep your cholesterol levels in check.

Although large-scale solvent processors dominate the commodity vegetable oil markets, they do have limitations: Hexane extraction plants can’t produce organic products because of the hazardous chemicals involved.

Driven by the growing demand for natural and organic ingredients, some processors are opting for greener extraction methods like aqueous-assisted enzyme extraction, extraction with green solvents like terpenes derived from citrus peels and tree oils, or mechanical expeller pressing instead of conventional hexane extraction. Mechanical extraction is growing in popularity to serve the organic market, leveraging equipment like QIE’s High-Shear Extrusion System to physically crush oil from the seeds without any chemical exposure—creating chemical-free, expeller-pressed soybean meal and high-quality oil.

Both mechanical and hexane extraction methods have their place in the oilseed market, serving distinct industry needs and demands ranging from organic food to biofuel to hundreds of different edible and industrial applications in between. Selecting the appropriate method for your plant depends on the type of oilseed you process and the end markets you serve.