Soybean oil refinery machines are designed to process crude soybean oil into edible-grade oil by removing impurities, free fatty acids (FFAs), pigments, and odors. The refining process typically includes degumming, neutralization, bleaching, and deodorization stages, ensuring high-quality edible oil.

When choosing a suitable soybean oil refinery machine, the following factors should be considered comprehensively:

Determine the daily or annual soybean processing volume according to your own production scale. For small – scale production, such as a small – sized edible oil processing workshop with a daily soybean raw material supply of several hundred kilograms, a refinery machine with a matching processing capacity can be selected. For large – scale production enterprises, a machine with a larger processing capacity is required to meet the production demand.(Read more: Small and Medium Scale Soybean Oil Mill Plant?)

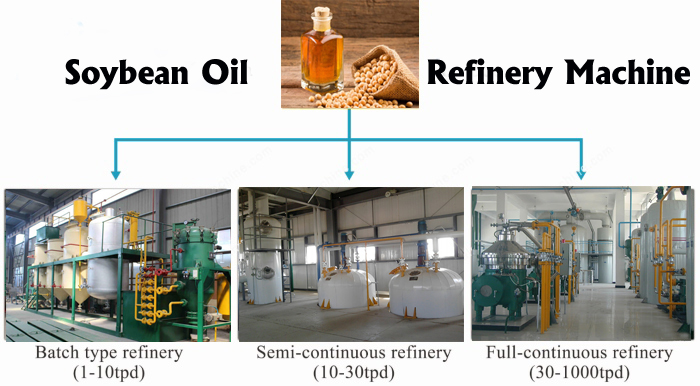

Batch – type Refinery Machines: Suitable for small – scale production, they are flexible in operation but have lower production efficiency and higher energy consumption.

Semi – continuous Refinery Machines: They are between batch – type and continuous – type, with a certain degree of automation and production efficiency, suitable for medium – scale production.

Continuous Refinery Machines: They have a high degree of automation, high production efficiency, and low energy consumption, suitable for large – scale production.

Research and Development Capability: A manufacturer with strong research and development capabilities can continuously improve and innovate equipment to meet different customer needs.

Production Scale: The production scale of the manufacturer, such as the workshop area and processing equipment, reflects its manufacturing level. A large – scale manufacturer is more likely to provide high – quality equipment.

Qualification Certification: The manufacturer should have relevant qualification certifications, such as ISO9001 quality management system certification and CE EU certification, to ensure the quality and safety of the equipment. (Related post: Establish A Small Scale Soybean Oil Production Line >>)

Technical Support: The manufacturer should be able to provide timely technical support, including equipment installation and debugging, process guidance, and technical training.

Spare Parts Supply: Ensure the supply of spare parts to reduce equipment downtime in case of failures.

After – Sales Guarantee: A good after – sales guarantee system, including the warranty period and warranty scope, can protect the rights and interests of users.

Price: On the premise of meeting production requirements and equipment performance, compare the prices of different manufacturers and models to choose equipment with a higher cost – effectiveness ratio. Do not simply pursue low – cost equipment, as it may bring problems such as poor quality and low efficiency.

Overall Operating Costs: In addition to the purchase price, also consider the long – term operating costs of the equipment, including energy consumption, maintenance costs, and labor costs, to comprehensively evaluate the cost – effectiveness of the equipment.

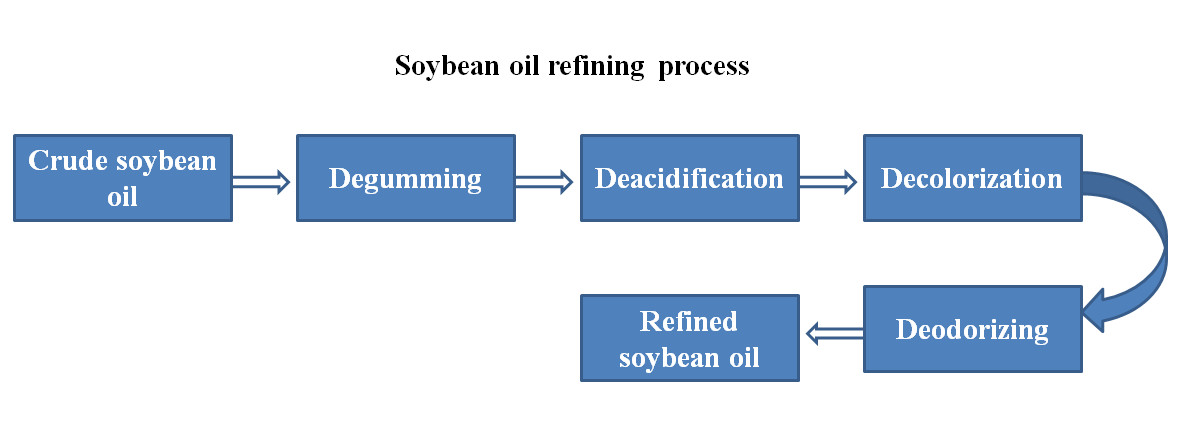

1. Degumming Section

Purpose: Remove phospholipids, gums, and proteins from crude soybean oil.

Process: Hot water washing (60-80°C) to hydrate impurities. Centrifugation separates hydrated gums from oil.

Key Equipment: Degumming tank, high-speed centrifugal separator.

2. Neutralizing (Deacidification) Section

Purpose: Eliminate free fatty acids (FFA) via chemical neutralization.

Process: NaOH solution reacts with FFAs to form soapstock. Soapstock is separated by centrifugal force.

Outcome: Acid value reduced to ≤0.1 mg KOH/g.

3. Bleaching Section

Purpose: Remove pigments, trace metals, and residual soap.

Process: Oil mixed with bleaching earth (activated clay) under vacuum (-0.09 MPa). Filtration removes spent adsorbent.

Result: Improved color (yellowish to pale yellow).

4. Deodorization Section

Purpose: Eliminate volatile compounds (off-flavors, peroxides).

Process: Steam distillation at 240-260°C under high vacuum. Four-effect heat recovery system to save energy.

Output: Odorless, stable refined oil.

5. Cooling & Winterization (Optional)

Purpose: Remove waxes and saturated fats for better clarity.

Process: Slow cooling to 4-10°C to crystallize waxes. Filtration via plate-and-frame press.

6. Filtration & Packaging

Final polishing filtration (diatomaceous earth) for clarity.

Automated filling systems for bottling/tank storage.