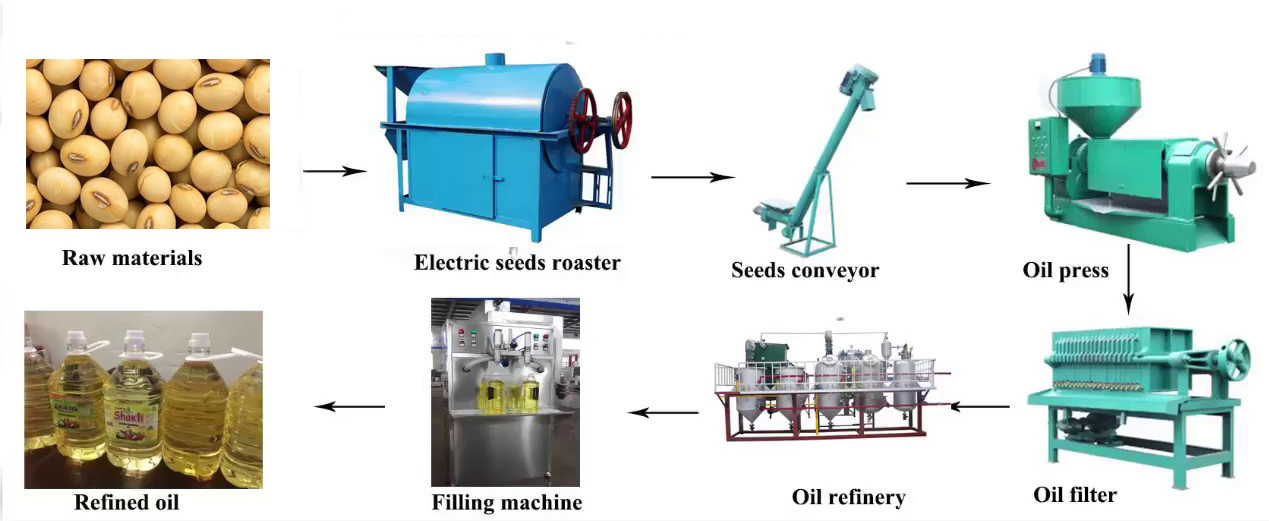

Our Small Scale Soybean Oil Processing Plant can perfectly meet all your expectations about soybean oil manufacturing. It just connects necessary soybean oil processing machine together by conveyors to form continuous and automatic soybean oil production. The common capacity of our small soybean oil mill is about 1~30 tons per day.

Brand

QIE

Raw Material

Soybean

Capacity

1-30TPD

1-30TPD

Customized Small Scale Soybean Oil Processing Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed soybean oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes soybean oil and soybean protein production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn MoreA basic small-scale plant needs the following core equipment:

Cleaning machine: Removes impurities (stones, dirt, broken soybeans) to protect downstream equipment and improve oil quality.

Seed conditioning equipment: Adjusts soybean moisture (typically to 8–10%) and temperature to enhance oil extraction efficiency.

Oil press machine: Uses mechanical pressure (screw press) to extract oil from conditioned soybeans; suitable for small scales due to low energy use.

Oil filter: Removes residues (soybean meal particles) from crude oil using cloth filters or centrifugal filters.

Storage tanks: For raw soybeans, crude oil, and by-product soybean meal.

Optional equipment (for higher-quality oil) includes a degumming machine (removes phospholipids) or deodorization unit (reduces off-odors), but these add to costs.

Crude soybean oil (unrefined) has a shorter shelf life of 3–6 months when stored in cool, dark conditions (below 25°C) in airtight containers. It is prone to oxidation due to residual impurities.

Refined soybean oil (after degumming, neutralization, and bleaching) can last 6–12 months under the same storage conditions, as refining removes most oxidation-causing compounds. Adding natural antioxidants (like tocopherols) or using nitrogen-flushed packaging can extend shelf life further.

The cost varies based on capacity, equipment quality, and automation level. For a 50–500 kg/day plant, the initial investment typically ranges from $5,000 to $30,000. This includes basic equipment (cleaning, crushing, pressing, filtering), a small processing space, and initial raw materials. For a 1–5 tons/day plant, costs increase to $30,000 to $100,000, as it may require semi-automated equipment, larger storage facilities, and additional refining steps (e.g., degumming or deacidification) for better oil quality. Additional expenses include permits, labor, and utilities.

Soybeans typically contain 18–22% oil by weight. In small-scale mechanical pressing (the most common method), the actual oil yield is 12–16% of the input soybeans. This is lower than large-scale solvent extraction (which yields 16–19%) because mechanical pressing cannot extract all oil. The yield depends on soybean quality (e.g., moisture content, variety) and press efficiency—well-conditioned soybeans (proper moisture/temperature) yield 1–2% more oil.

Small-scale refining focuses on basic steps to improve oil quality for edible use:

Filtration: Removes solid particles using filter presses or cloth filters.

Degumming: Uses water or acid to precipitate phospholipids (gums), which are then separated by centrifugation or settling.

Neutralization: Adds a weak alkali (e.g., sodium hydroxide) to remove free fatty acids, forming soapstock that is separated.

Bleaching: Uses clay or activated carbon to remove pigments (e.g., chlorophyll) and improve color.

Small plants often skip deodorization (which requires high heat/vacuum) to reduce costs, resulting in oil with a mild soybean odor, acceptable for local markets.

The primary by-product is soybean meal—the solid residue left after oil extraction, containing 40–48% protein. It is highly valuable as:

Animal feed (for poultry, swine, and aquaculture) due to its high protein content.

Organic fertilizer (if low-quality or mixed with impurities).

Other minor by-products include soapstock (from neutralization) used in soap making, and gums (from degumming) used in food additives or industrial applications.

Moisture content: 10–12% (too high causes mold; too low reduces press efficiency).

Purity: Less than 2% impurities (stones, dirt, damaged seeds) to avoid equipment damage.

Oil content: Preferably 18% or higher (varies by variety; e.g., high-oil soybeans are ideal).

Freshness: Avoid old or moldy soybeans, which can introduce off-flavors or mycotoxins (harmful to health).

Regulations vary by country but typically include:

Business license: To legally operate the plant.

Food safety certification: For edible oil (e.g., FDA approval in the U.S., FSSAI in India) to ensure compliance with hygiene and quality standards.

Environmental permits: To manage waste (e.g., wastewater from cleaning, solid waste from meal).

Fire safety clearance: Due to flammable materials (oil, fuel) and electrical equipment.

Local authorities may also require inspections of processing facilities, storage areas, and worker safety measures.

Profitability depends on factors like input costs, oil price, and market demand. A 1-ton/day plant processing 300 days/year can produce ~150 tons of oil (15% yield) and ~850 tons of meal annually.

Soybean cost: $400/ton,

Oil selling price: $1,200/ton,

Meal selling price: $300/ton,

Annual revenue is ~$180,000 (oil) + $255,000 (meal) = $435,000. After deducting costs (soybeans: $120,000; labor, utilities, permits: ~$50,000), net profit is ~$265,000. Profit margins are higher in regions with high local demand for affordable edible oil and animal feed.