Setting up an soybean oil mill plant is indeed a great investment as it returns good profit. But then again, starting one can be very exhausting, especially if you do not know how to choose the right soybean oil mill machinery.

The small scale soybean oil production plant we supplied ranges from 1 tons per day to 30 tons per day. Compared to large scale type, small scale soybean oil processing plant costs less, requires less maintenance and power consumption, but has the full functions of soybeanoil production. If you choose us, we will offer the most favorable price to help you set up the small scale soybean oil mill plant.

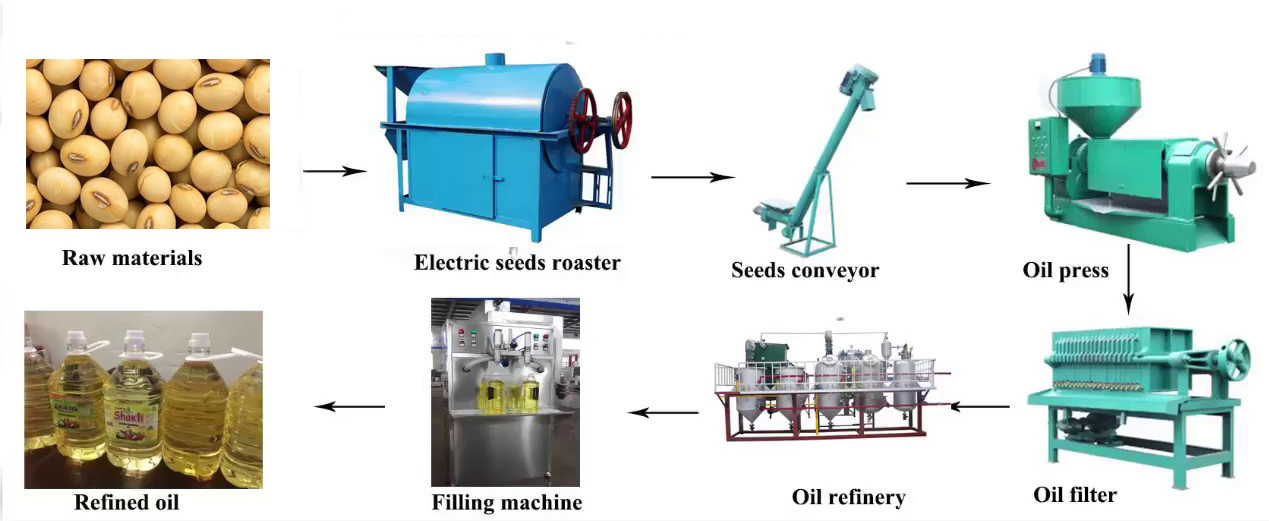

Small soybean oil processing plant connects small types of soybean oil processing machines together to realize the continuous oil manufacturing. Generally, the main machine for a small scale oil processing plant has cleaning sieve, cooker, oil press machine and oil filter press.The cost of a 5tpd groundnut oil mill plant that is designed with manual elevators may cost at least $5,500 or above. In most case, different equipment selection, different oil production process and other factors can the final price.

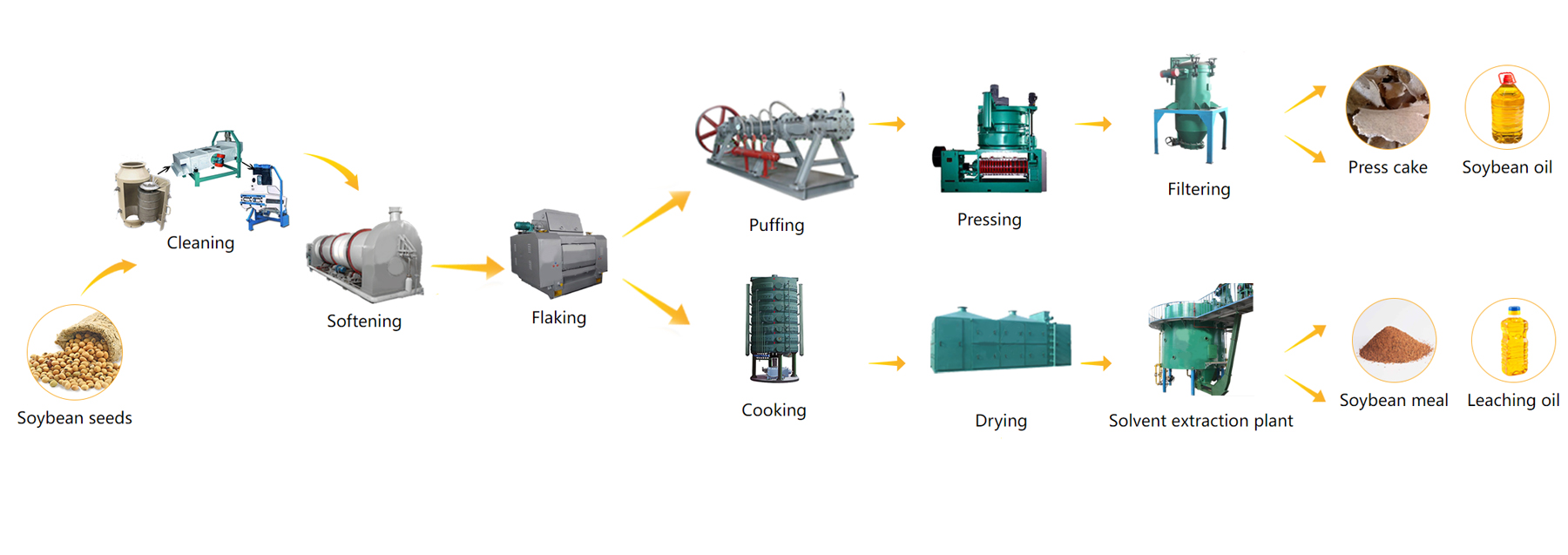

If the output of soyabean oil is more than 30T per day, you had better buy a complete soybean oil production line. It is mainly composed of soybean pre-treatment process, soybean pressing plant, soybean oil solvent extraction plant and crude oil refining plant.

Soybean pretreatment equipment is used to clean the impurities in soybean, making the temperature and water of soybean meet the pressing and leaching conditions through crushing, softening, rolling embryo and other processing techniques, so that the efficiency of soya oil pressing and extraction will also be improved.

Oil pressing process is equipped to press the majority oil out from the soybean, large scale soya oil press machine for sale is manufactured to meet large oil production.

But due to the not so high oil content of soybean (15.5%-22.7%), solvent extraction is usually used to get more oil from the soybean cake, thus realizing higher economic benefits. After the solvent extraction, the residual oil ratio can be reduced to 1%, and the soybean meal cake can also be used for producing animal feed.

Soya oil refining plant is the last process of building soya oil production line, used to process the crude oil from the solvent extraction. Through the process of degumming, deacidification, decolorization and deodorization, the harmful and useless substances from the crude oil can be removed, at the same time, the color and smell of the soya oil can meet the standard of edible oil.

Just like any equipment, soybean oil mill machineries are made to perform certain processes, which include cleaning, expelling, flaking, crushing, cooking, pressing, and filtering. Below are two of the most common processes:

Therefore, prior to choosing one, familiarize the processes involved in turning the raw material you have to oil. Not only will this save you from any unexpected expenditure. It will also speed up processing of soybean oil.

Although typical soybean oil mill machinery has a capacity range of 10 to 500 TPD, in most cases, manufacturers can customize. QIE Machinery can design one unit to meet every need of a project.