QIE Machinery is a reliable manufacturer of vegetable oil machine including screw oil press, oil expeller press, mechanical oil pressing machine, solvent oil extraction machine, and also customized cooking oil production line and soybean oil mill production line/equipment. Over 30+ years of experience in equipment manufacturing and project construction has proved our strong ability and great product quality.

After sealed screw conveyor put the puffed soybean into exactor, the oil in extruded soybean will be dissolved by solvent, finally get crude oil. Compared with the pressing method, the residual rate of leaching is low (<1%) and offer a better quality meal. At the same time, this solution has the following features:

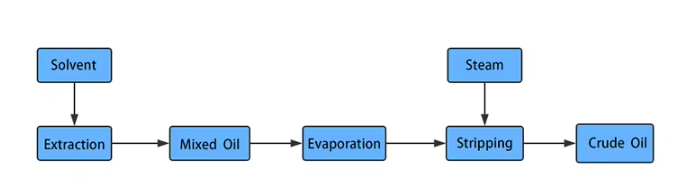

Extraction: It usually adopt an organic solvent that can dissolve the oil, through the material spray, soak, so that the oil will be extracted from the oil-bearing seeds.

DTDC: By continuously the multi-layered steam heating, the heat obtained by the solvent in the wet mash is vaporized, thereby separating the solvent from the wet meal, and removing the solvent remaining in the wet meal as much as possible.

Evaporation: The difference between the boiling point of the oil and the solvent is used to separate the solvent and the oil.

Stripper: The separated solvent can be dissolved in the selected paraffin or solvent and recovered.

| DEGUMMING |

The purpose of degumming is to remove the phospholipid, sugar, protein, trace mental, and some other impurities, which have bad effect on the stability of the oil. First, the oil should be heated to 90 to 105°C, then put some phosphoric into it and stir. It mainly transfer the phospholipid to that can be compatible with water. Then add some salt water to gather the impurities, which subside to the bottom and be discharged.

|

|||

| DEACIDIFICATION | Add some certain quantity of alkali to neutralize the free fatty acids. During this process, some soap stock will be produced.The soap stock will be separated from the oil after using the centrifugal machine. | |||

| DECOLORING | Mix the oil with activated clay in the oil soil mixing tank, and 1 ton oil needs 5kg clay. Then stir it 10 minutes at 10°C. Next, pump the mixed oil into the decolorization tower. It use steam to heat the mixed oil at 100°C, and the process lasts 30-40 minutes. | |||

| DEODORIZING | The main purpose of deordorization tank is to remove fatty acid and some odor material. The principle of the deordorization is to use the high temperature and vacuum to remove the odor. The fatty acid and odor will be stalled in the storage tank. | |||

| DEWAX | Dewaxing can improve oil palatability,so it plays an important role to the quality of finished oil.At the same time, dewaxing can improve oi transparency and brightness.It is necessary to dewax for some oils such as maize oil, rice bran oil, sunflower oil and cottonseed oil. At present , wintering method is very popular to deawxing. The crystallizing rate crystallizing temperature, maturing time vary with oil features. | |||

We are offering the factory price soybean oil processing machines and providing complete soybean oil production line in many countries around the world, including Mexico, Panama, Pakistan, Thailand, Kazakhstan, Malaysia, Sri Lanka, Philippines, Uzbekistan, Chile, Brazil, Jamaica, Nigeria, Argentina, Ghana, Ethiopia, Russia, Australia, USA, Cameroon, Somalia, Uganda, UK, Moldova etc..