Soybean oil is the world’s 2nd largest vegetable oil crop. The soya bean is mainly composed of oil (20%) and proteins (Approximately 40%). The rest of the bean is carbohydrate and ash. Soya protein is the only vegetable source of complete protein which contains all the essential amino acids required by humans and animals.

It also contains linoleic (omega-6) and alpha-linolenic acid (omega-3), both polyunsaturated fatty acids that are essential nutrients but also increasingly recognised to reduce the risk of chronic age-related diseases such as cancer and cardiovascular disease.

Nigerian consumption of soybean oil is projected to reach 88 thousand metric tons by 2026, up from 85 thousand metric tons in 2021. This marks an annual growth rate of 0.6%. Since 2017, Nigerian demand for the oil has increased by 2% annually. Meanwhile, Nigerian production of soybean oil is predicted to reach 139 thousand metric tons by 2026, up from 112 thousand metric tons in 2021. This represents an average annual growth rate of 3.5%. Since 1993, Nigerian supply of the oil has been on the rise, increasing by 5.2% annually.

If your are planning to setting up a soybean oil production plant in nigeria you are in the right place! QIE Machinery is a senior soybean oil production plant manufacturer. We are expert in soybean oil processing line for both small, medium and large production plant, with rich experience in palm oil plant designing, equipment manufacturing, factory installation and oil mill commissioning.

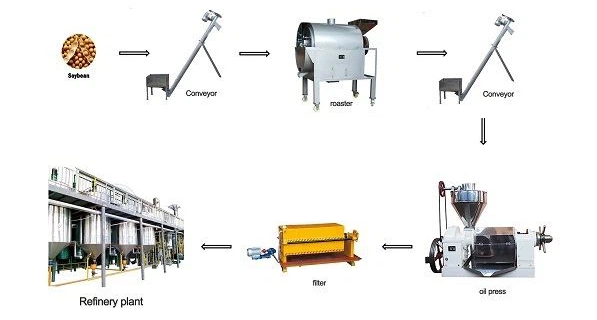

Soybean oil manufacturing process through a machine is not an overly complicated process. Anyone with drive and determination can start their own mini or small scale soya oil plant. The most important part of the process is to understand how to extract oil from soya beans, what equipment is required and how much it would cost. When starting a small soybean oil processing plant, you will need to invest in soybean oil processing machines.

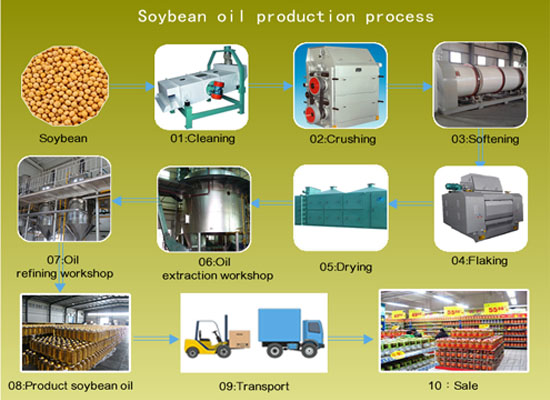

Cleaning Machine

To make sure the soybean oil produced has a high quality, the soybean is first cleaned in a cleaner properly. Seed cleaning machine removes dirt, rocks, and all other impurities that can reduce the quality of soybean oil. The raw material is then dried with the help of a drier and then the soybean is de-hulled to remove its hulls. These hulls can absorb oil and reduce the overall oil yield. That is why their separation is essential.

Cooking Machine

To increase soyabean oil yield, a cooking machine is used to adjust the moisture content so that a large moisture content does not affect the quality and quantity of oil. In this machine, soybean is heated at a temperature ranging from 60 and 88 °C.

Soybean Oil Press

Soybean oil expeller press is an important machine used in small or mini soybean oil plant. The processed and cleaned soybean is fed in oil pressing machine. In the pressing chamber, the soybean is pressed with the help of a pressing ring and pressing worm. Due to the pressure, crude oil starts coming out of the soybean.

Oil Filter Machine

Soybean oil produced in the above step is in its crude form. It must be filtered properly to remove all organic impurities from the crude oil. For this purpose, an oil filter machine is used. It filters the crude oil and separates fatty acids and other volatile compounds that can produce a bad odor and affect the quality of soybean oil.

Soybean Oil Refining

The filtered oil is further refined in oil refinery plant to increases the quality of oil and make sure no other impurity (phospholipids, off-flavor, pigments, and other impurities) is left behind. In a min or small scale soybean oil plant, soybean oil refining machine is optional. You can choose to equip small scale soybean oil refining machine or not, which all depends on your soybean oil business plan and investment budget.

To start an soybean oil processing business in Nigeria, get the best oil processing equipment from QIE Machinery. All soybean oil mill machinery purchased from QIE Machinery is customized for each customer depending on their needs. Discussions take place to know the best processing process to choose as well as the equipment type and size. The soybean oil processing process must match the production capacity of your business.

1) Weighing: The Raw-stuff, Soybean is firstly stored in Buffer Tank which is for adjusting the Soybean flow. By means of Weighter the processed Soybean is weighted and the imputing quantity is accumulated.

2) leaning and Impurities separating: By means of Vibrating Sieve the larger and smaller size impurities in Soybean are removed out.

3) Gravity De-stoner & Magnetic Separating: some impurities which are as almost same size as Soybean are still mixed in Soybean, but as their gravity or nature properties are different, by means of Gravity De-stoner and Magnetic Separator , the heavy stone and ferric impurities are separated out from Soybean.

4) Crushing & De-hulling: In order to increase protein content in Soya Meal, the de-hulling process is very significant. De-hulling system is composed of Cracking by two Crushing Mill which breaks Soybean into small pieces, and twice separating by Aspirators which separates Soy Hull out from Soya Meal.

5) Flaking: Flaking Machine is adopted for flaking Soya Meat into thin Flake, during which Soybean cell tissue is destroyed.

6) Extrusion puffing: The Soya Flake is fed into Expander in which heat is produced with the functions of kneading, friction between the spiral shaft and inner wall of the Expander, meanwhile eject in steam to increase Soya Flake temperature.

7) Drying & Cooling: Jetting out from the end of expander, the Soya Cake is very moist and hot , it should be dried at moisture content 9.5% or so, and cooled down to about 60℃ by counter-current-wise down in Cooling Dryer, and then the dried Soya Cake is conveyed into Extraction workshop.

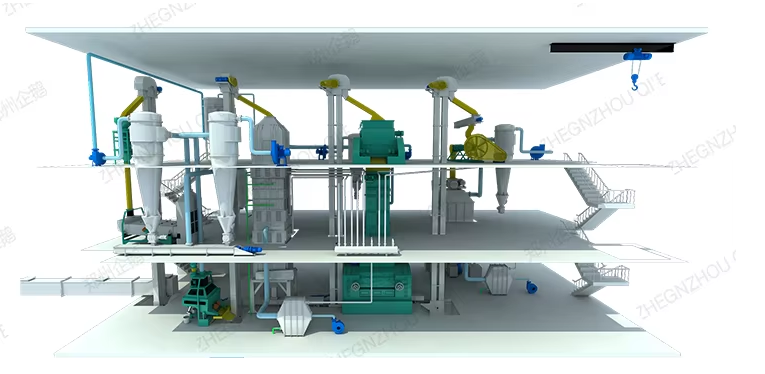

1) Oil Extraction system: for extracting oil from Expanded Soya Cake to get Miscella which is mixture of Oil and Hexane;

Wet Meal Desolventizing System: for removing Solvent from Wet Meal as well as to toast and dry Soya Meal for getting proper finished Meal Product qualified for animal feed;

2) Miscella Evaporation System: for evaporating and separating Hexane out from Miscella under negative pressure;

3) Oil Stripping System: for thoroughly removing residual Solvent to produce standard Crude Oil;

Solvent Condensing System: for recovering and circulating use of Hexane;

4) Paraffin Oil Recovering System: further recovering residual Hexane gas remains in vent air by means of Paraffin Oil to reduce Solvent consumption;

1) Hydrating & Degumming: The Crude Oil firstly is filtered by Filters for removing out mechanical impurities out from, and then has heat-exchange in Heat Exchanger with hot Refined Oil, next is heated by Heater to the appropriate temperature. After being mixed with hot water by Mixer , it is pumped into Hydrating Reactor in which most phospholipids will be hydrated into flocculent Lecithin Gum.

2) Neutralizing & Degumming: Adding in appropriate Lye by Dosing Pump and mixing them by Mixer , the oil is pumped into Neutralizing Reactor in the hydratable phospholipids as well as acid are saponified into Soapstock Gum.

3) Washing: There are residual soapstock still remains in degummed and neutralized oil. Adding Hot Water and mixing with oil by Mixer, the residual soapstock will be solved completely into washing water.

4) Bleaching. The Degummed Oil firstly heat-exchange in Heat Exchanger with hot Refined Oil, next is heated by Heater up to 110℃. And then enters into Oil-Clay Mixer in which it is mixed with Bleaching Clay. next the mixture of oil-clay enters into Bleaching Tower in which the most pigment in oil will be adsorbed by Bleaching Clay.

5) Deacidifying & Deodorizing: The Bleached Oil contains some odouring substance which mostly are free fatty acids. By means of Assorted De-acidifying & Deodorizing Tower, under high temperature and vacuum condition, these free fatty acids will be stripped out from oil. The odouring substances are caught in Fatty Acid Scrubber and collected in Fatty Acid Tank .

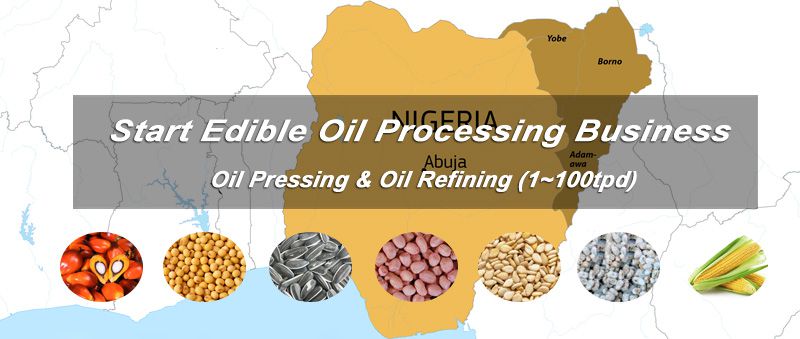

As of 2010, about 30% of Nigerians are engaged in agriculture. Agriculture was once the main source of foreign exchange earnings in Nigeria. The main oil crops in Nigeria include palm kernel, palm fruit, soybean, peanuts (groundnuts), sunflower, safflower, sesame, castor bean, mustard, cotton seed, corn and flax seeds. Therefore, there are rich sources to start edible oil processing business in Nigeria. In addition, there are growing demands for high quality edible oils with the the improvement of people’s living standard in Nigeria. So, how to start it? And How much it may require?

Just like any other business, it is necessary to have the feasibility report and business plan to ensure the success of your oil processing business. Here we listed the general steps to start edible oil production business in Nigeria, you can have a reference. But, perfect oil mill business plan is based on your actual requirements and conditions. Contact us to get the customized Oil Making Machine for Business in Nigeria.

* Prepare an In-depth Analysis of Local Oil Manufacturing Market

* Draft Customized Business Plan

* Raise Funds and Prepare the Factory Land

* Choose Reliable Oil Processing Machinery Supplier

* Oil Mill Plant Installation, Commissioning and Production

* Craft Edible Oils Marketing Promotion Plan