Soybean oil is a vegetable oil extracted from soybean (Glycine max) legumes. It is one of the most widely consumed cooking oils and the second most consumed vegetable oil. As a drying oil, processed soybean oil is also used as a base for printing inks (soy ink) and oil paints.To produce soybean oil, the soybeans are cracked, adjusted for moisture content, heated to between 60 and 88 °C (140 and 190 °F), rolled into flakes, and solvent-extracted with hexanes. The oil is then refined, blended for different applications, and sometimes hydrogenated. Soybean oils, both liquid and partially hydrogenated are sold as “vegetable oil”, or are ingredients in a wide variety of processed foods. Most of the remaining residue (soybean meal) is used as animal feed.

QIE Machinery has rich experiences in designing and installing soybean oil mill plant projects. We are happy to provide you technical supports for your soybean oil manufacturing business, from soybean seed cracking to final soybean oil refining. Welcome to contact us to get more technical parameters and detailed price list for soybean oil processing machines!

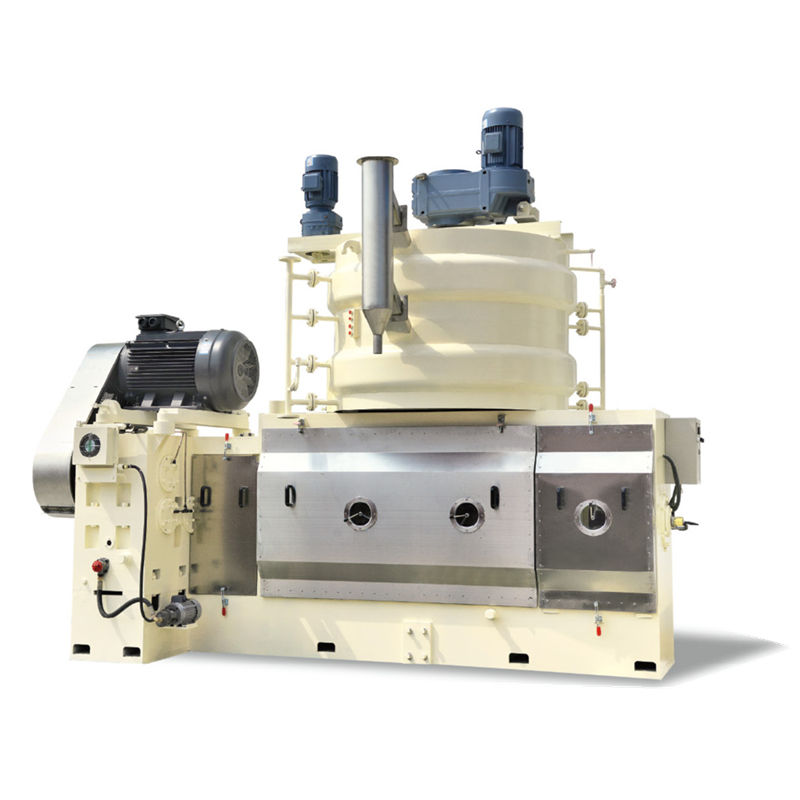

How to make soybean oil? Mechanical pressing entails crushing the soybeans to extract oil, yielding cold-pressed or expeller-pressed varieties with distinct flavors. Solvent extraction employs a solvent like hexane to dissolve the oil from soybean flakes. Residual hexane is then removed from the oil.

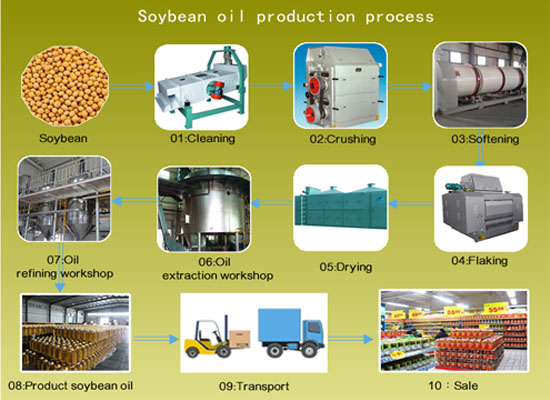

The production of soy bean oil is complicated. Below are the basic steps of the soybean oil production plant

First, sovbean should be cleaned and sorted manually/mechanicaly to separate the foreign matter, dust, dirt and stone particles, admixture of other seeds, husks, immature, split, shriveled, damaged and diseased grains. The seed cleaner machine are used to clean the soybeans. To remove the iron from the seeds, the magnet is used.

Two common soybean oil production processes are solvent extraction(chemical) and mechanical extraction using a screw press.

Solvent Extraction (Chemical – Solvent extraction is the process of removing a solute component from a solid using a liquid solvent; This is called leaching or solid-iguid extraction. According to this method, n-hexane produces a higher amount of oil than other solvents.

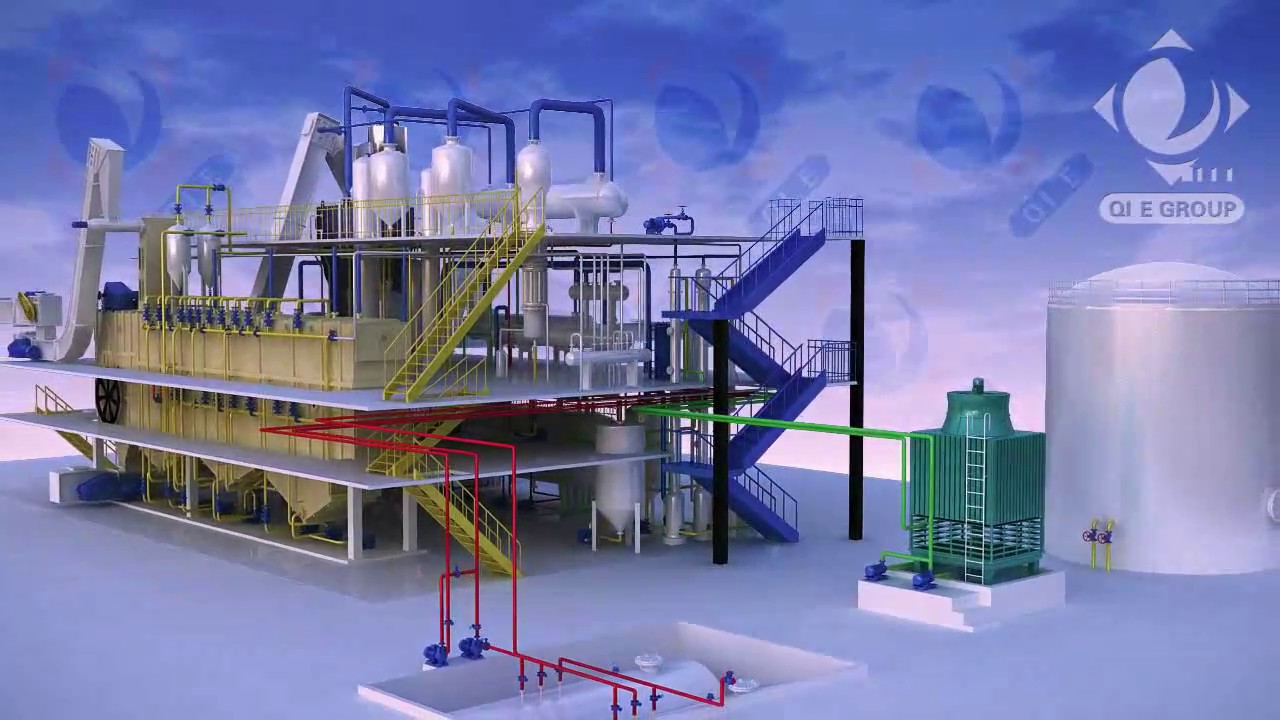

Oil Refinery is a very important part of the processing process because the oil contains impurities like phospholipids, pigment and off-flavor which need to be removed to make the ol edible. The oll insoluble impurities are removed through filtration process while the soluble materials are removed bv diferent processes.

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. QIE Machinery will customize the oil refinery process and solution for each of customer depending on their specific situation and needs.

So called “refinery”, generally refers to deacidificationprocess. But in the broad sense, oil refinery process includes crude oil pretreatment, degumming, deacidifying, decoloring, deodorization, degreasing, and dewaxing process, etc. We will design the refining process depending on the quality requirements of refined oil.

For example, according to the relevant quality standard, edible oil refinery for soybean, peanut, and sesame, only needs pretreatment and degumming, and cottonseed oil refinery needs pretreatment, degumming and deacidifying, and rice bran oil refining needs pretreatment, degumming, deacidifying,decoloring, deodorization and dewaxing process to each the standard of cooking oil.

Soybean Oil Plant Size and Capacity

The size of the soybean oil plant has a large effect on total cost:

Small-scale soybean oil extraction machine generally has higher costs per ton due to lower production capacity, so in the long term, large-scale plants will be much more profitable.

In the latest study of IMARC, soybean oil production market includes industry trends, raw materials, plant setup, manufacturing process, cost, soybean oil machine, and revenue which offers a techno-commercial roadmap to set up a soybean oil processing plant. The study which has been done by one of the leading research and advisory firms of the world covers all the required facets of the soybean oil production market.

This ranges from an overall overview of the market to extremely small details of the performance of the industry, manufacturing and processing requirements, project funding, project cost, project economics, profit margins, expected returns on investment, etc. This whole report is a must-read for investors, entrepreneurs, researchers, business strategists, consultants, and all those who are planning for foraying into the industry of soybean oil in any way.