Soya oil is usually called soybean oil, pressed out from soybean with oil content of 15.5%-22.7%, which is one kind of common oil plant. As one of the frequently-used edible oil, soya oil has high demand in the edible oil market.For entrepreneurs interested in investing in the oil processing industry, seizing this opportunity to start a soybean oil refining business would be a potentially rewarding decision.

Starting a soybean oil refining line requires careful planning, understanding the production process, and securing the necessary investment. Below is a step-by-step guide to help you develop a robust business plan.

Before investing, conduct thorough market research to understand the demand for soybean oil in your target region. Analyze competitors, pricing trends, and potential customer segments (e.g., food manufacturers, retail consumers). Reports from industry analysts can provide valuable insights into market size and growth projections. Register your business and obtain the necessary licenses and permits. If you plan to operate internationally, consider registering a company in a business-friendly jurisdiction like Hong Kong, which offers flexible regulations and tax benefits(Read More: Advanced Soybean Oil Production Line Solutions)

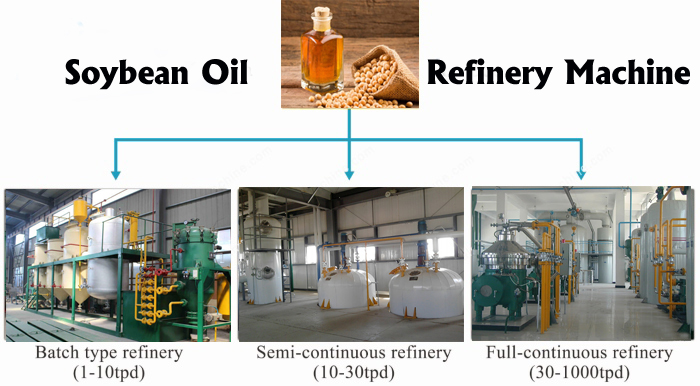

Batch Oil Refinery Line 1-20TPD

Batch oil refinery is one of the main kinds of oil refinery methods, which is suitable for various vegetable and animal oils, such as soybean oil, peanuts oil, sunflower oil, rape seeds oil, cottonseeds oil, coconut oil, palm oil, niger seeds oil, rice bran oil, fish oil, seal oil, etc. It is suitable for small capacity, 1TPD to 20TPD, which contains Degumming, Neutralizing, Decolorization and Deodorization section. As a result, it can also be called small edible oil refinery unit.

Semi-Continuous Oil Refinery 10-50TPD

The semi-continuous oil refinery process design is based on batch type but higher than batch type.

Compared with batch oil refinery line, semi-continuous oil refinery process is more efficient. At the same time compared with fully continuous oil refinery plant, Semi-continuous oil refinery process needs less investment cost. The semi-continuous oil refinery capacity can be designed according to customer requirement. It’s suitable for the middle type oil refinery plant from 10TPD to 50TPD. So it is also called middle scale oil refinery unit.

Continuous Oil Refinery Plant >30TPD

Continuous Type Oil Refinery Plant is recommended against the batch refining for higher capacity plants above 30 tons per day and for oils containing higher FFA content. This process line is bit expensive than batch oil refinery process but it provides superior quality refined oil along with automation system and low processing cost. It is also a large edible oil refinery unit.

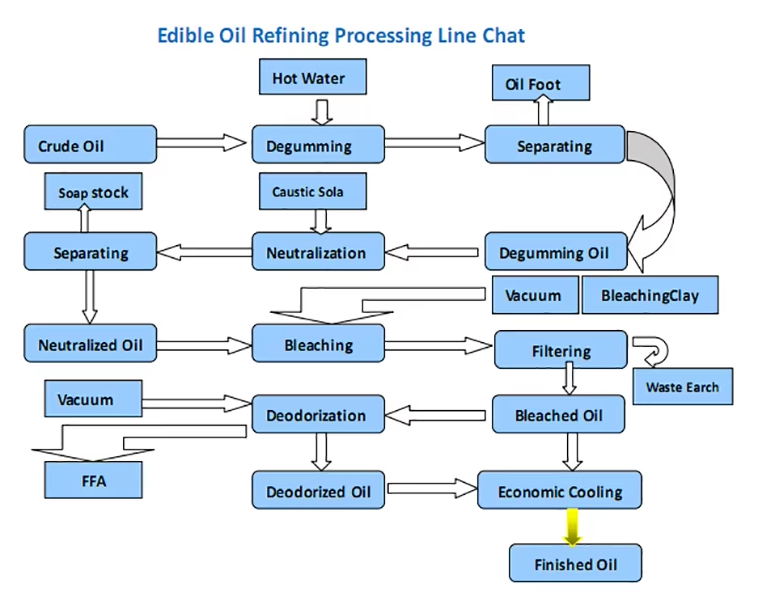

Neutralization Process

The crude oil is pumped to Neutralizer from oil mill or storage tank & first it is treated with weak solution of phosphoric acid or other suitable degumming agent for removing gums. Neutralizer is used remove the Free Fatty Acids (FFA) by adding caustic soda. Oil is heated up to about 60°C by heating coils and oil is stirred by the stirrer. The chemical reaction between free fatty acid and caustic soda forms the soap stock. This soap stock is allowed to settle down in the neutralizer from where it is collected into the soap pans. The oil is then washed with hot water to remove traces of soap particles and free alkali.

Bleaching Process

In the bleaching process of batch type vegetable oil refinery plant, excess color from the oil is removed. Neutralized oil is heated in the bleacher vessel to remove excess moisture and thereafter it is treated with a measured quantity of bleaching earth and activated carbon. Nextly oil passes through a filter to separate bleach earth and bleached oil. Oil obtained after bleaching process is light in color and has good golden type appearance.

Deodorization / Deacidification Process

The deodorization process removes odor from the oil to improve the quality and self-life of the oil.The deodorization process is important The clean bleached oil is heated in the deodorizer to remove all the odiferous material such as phenols, ketones, tocopherols, aldehydes etc. The oil is heated in the deodorizer above 110°C through thermic fluid coils and then live steam is given to the oil from the bottom steam nozzles and temperature of oil is raised up to 200 to 220°C through thermic fluid coils. Entire process is done under high vacuum. Thus smell is removed from the oil in the deodorizer.

Cooling Process

The deodorized oil needs to be cooled at the atmospheric temperature to avoid oxidation. The deodorized oil is cooled in the cooler vessel. The water circulating coils take away the heat and the oil is cooled.

Once the process cycle is complete the oil obtained will be RBD oil which is light in color. After cooling it will pass through polishing filter to obtain sparkling light color & odorless oil for packing, which will be used as final edible oil for cooking.

De-waxing Process

Dewaxing process is carried out for Sunflower and Rice Bran Oil as they contain waxes compared to other oil. This wax is removed by the dewaxing process. The oils are subjected to winterization process. The oil is first processed in the crystallizer where it is cooled by chilled water circulation. Low temperature results in the formation of crystals which are removed in the filtration process.

Thermic Fluid Boiler, Vacuum Pump, Barometric Condenser, Catchalls, Steam Generator etc. play their role in the refining process. So these equipments are part of the batch type vegetbale oil refinery plant and connected with the vessels through pipelines.

Calculate your total costs, including:

Raw materials (soybeans, chemicals).

Labor, utilities, and maintenance.

Marketing and distribution.

Revenue depends on the market price of soybean oil and your production capacity. A well-run refinery can achieve profitability within a few years.

Soybean Extraction Plant for Seed:

The soybean seed extraction plant is the first step in the soybean oil extraction process. It involves cleaning and crushing the soybean seeds to extract the oil. By setting up a soybean seed extraction plant, you can ensure a steady supply of raw materials for your refinery plant.

High-Quality Oil:

The soybean oil extraction process involves refining the crude oil to remove impurities and improve its quality. By setting up a soybean oil refinery plant, you can produce high-quality oil that meets international standards. This will help you attract customers who demand high-quality oil for their cooking and other needs.

Diverse Product Range:

A soybean oil refinery plant can produce a wide range of products, including cooking oil, industrial oil, and biodiesel. By diversifying your product range, you can cater to different customer needs and tap into different markets. This will help you increase your revenue and profitability.

Cost-Effective:

Setting up a soybean oil refinery plant can be a cost-effective investment in the long run. By producing your own oil, you can save on the cost of purchasing oil from suppliers. Additionally, you can sell the by-products of the soybean seed extraction process, such as soybean meal and soybean hulls, for additional revenue.