Soybean oil is among the most commonly used edible oils in the world and is valued for its versatile use as a cooking ingredient in food manufacturing.

A small-scale soybean oil production line is an integrated system of machinery designed for the efficient, physical extraction and refining of oil from soybeans, suitable for small to medium-scale operations with lower investment costs. The typical line includes a cleaning sieve, a soybean cooker, a screw oil press or expeller, and an oil filter press to yield edible oil. These compact, user-friendly lines can be customized for high oil output, are versatile for other seeds, and require minimal space and a small workforce, making them attractive for new and established businesses looking to diversify into oil production.

This soybean oil manufacturing unit is effective, automated and affordable which makes it ideal choice for small scale soybean oil factory. It is capable of continuous cooking oil processing plant.

The Small Scale Soybean Oil Production Line incorporates several essential components that facilitate the oil extraction process:

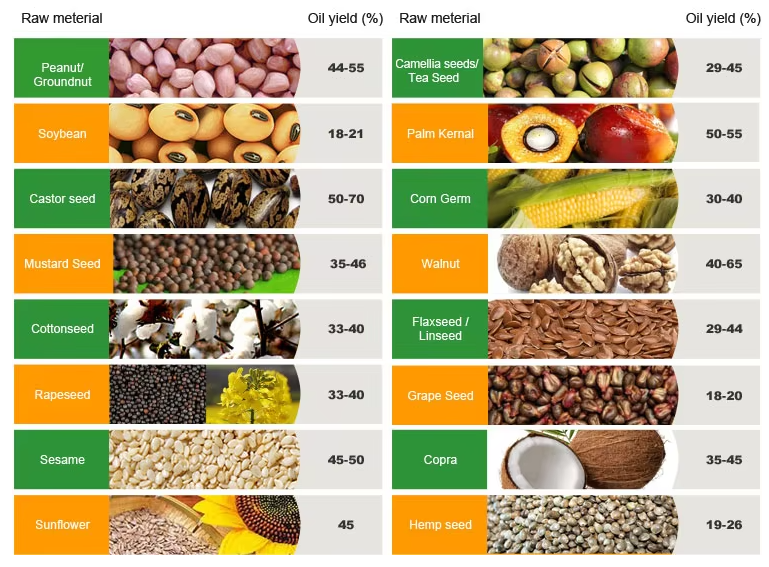

Our small scale soybean oil production line is suitable to process a great deal of raw materials, including peanut/groundnuts, sunflower seeds, jatropha seeds, black seeds, niger seeds, hemp seeds, rape seeds, grape seeds, sesame seeds, copra, cottonseeds, tea seeds and more.

A soybean oil mill machine is a specialized piece of equipment used for extracting oil from soybeans. This oil is used in a wide range of food products, cosmetics, and industrial applications. It is among the most widely consumed cooking oils globally.

A soybean oil mill machine typically works through either mechanical pressing or solvent extraction to separate the oil from the soybeans. The most efficient soybean oil plants use a combination of mechanical extraction and solvent extraction – this allows the extracted oil to retain its natural qualities while the manufacturer can maximise the oil yield from a given quantity of raw materials. Based on the approach you choose, you may have to invest in more than one extraction machine.

Tips for buying a soybean oil machine

Before you purchase a soybean oil mill machine, we recommend that you keep the following tips in mind to ensure you’re making the right decision:

Determine your production needs. Evaluate how much oil you need to produce per day. This will help you decide on the capacity and scale of the machine you require.

Choose a reliable manufacturer. Look for a reputable manufacturer with a track record of providing high-quality, durable machines. QIE Machinery has earned a solid reputation for producing reliable and efficient soybean oil machines that cater to both small and large-scale operations.

Consider total operating costs. Beyond the initial purchase price, factor in ongoing costs like maintenance, energy consumption, and spare parts. Machines with higher energy efficiency and low maintenance requirements can help reduce long-term costs.

Check for warranty and after-sales support. A good warranty and after-sales service can provide peace of mind and ensure that you have support if any issues arise with your machine.

Soybean is the top ranking oilseed produced globally, with total production reaching over 385 million MT during the current year 2021-22. Production of soybean oil ranks second to palm oil, reaching over 60 million MT in the current year. Soybeans, soybean oil as well as the meal are globally traded commodities and their production, international trade and consumption are tracked by various industry players and financial institutions. This blog discusses the commercial aspects of these soybean products over the past few years.

The following Table 1 presents global production, imports, exports, crush and ending stocks of soybean, for the last five years – from 2017-18 to 2021-22.