QIE Machinery is leading supplier of complete plants, equipment, and engineering services for soybean oil processing industry with capacity from 10TPD to 2,000TPD. We pride ourselves on having a cutting-edge manufacturing and R&D platform that ranks among the best in the world. Our focus is on building efficient and effective soybean oil extraction factories that are tailored to your unique needs. We offer a comprehensive package of services, including consulting, planning, design, research and development, equipment manufacturing, installation, commissioning, and training. Our primary goal is to create maximum value for you and bring your vision to life.

Pretreament workshop — solvent extraction workshop– Oil refinery workshop– Oil Filling workshop.

Pre-treatment process feature:

1) Different combinations of process can oil processing various oil plants in one workshop.

2) Use special intensified pre-treatment technology for aroma soybean oil to make it more aroma.

3) Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

4) Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

5) The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

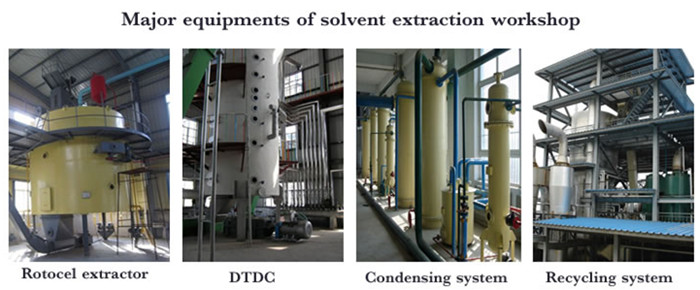

Extraction workshop Brief Introduction:

In our design, the Extraction line is mainly made up following systems:

Oil Extraction system: for extracting oil from pressed cake to get Miscella which is mixture of Oil and Hexane;

Wet Meal Desolventizing System: for removing Solvent from Wet Meal as well as to toast and dry Meal for getting proper finished Meal Product qualified for animal feed;

Miscella Evaporation System: for evaporating and separating Hexane out from Miscella under negative pressure;

Oil Stripping System: for thoroughly removing residual Solvent to produce standard Crude Oil;

Solvent Condensing System: for recovering and circulating use of Hexane;

Paraffin Oil Recovering System: further recovering residual Hexane gas remains in vent air by means of Paraffin Oil to reduce Solvent consumption;

Refinery workshop Introduction:

Soybean oil refinery plant includes a series processing process such as degumming, neutralization, bleaching, deodorization and so on. In general there are two methods of soybean oil refining process, one is physical refining and the other is chemical refining. However, no matter what kinds of refining methods, they are all done with the help of various oil processing equipment and machinery. What’s more, soybean oil refining machine are used to refine almost all kinds of oil extracted from oil seeds like sunflower seeds, peanuts , sesame seeds, and soya bean seeds etc. After refining, we can get refined, bleached, deodorized oil. That is, first-grade soybean oil.

1.soybean: It is a main kind of oil seed . It’s used to make soybean oil around the world. The oil content in soybean is about 15-20%.

2. Magnetic box: Clearing the iron impurity which might be in the soybean. The iron impurity will be harmful to the following machines, so we need take the iron impurities out.

3.gravity destoner: to remove the small stones in oil seeds.

4. Cleaning: This parts have different size cleaning sieves to clean the different impurities. After going through this part, most of the impurities are moved from soybeans.

crusher: the oil seeds should be crushed before softening section.

5. flaking machine: It is the process of making use of the mechanical action to flake the soybean into flakiness. After flaking, the material becomes thinner than before, it is good for absorbing moisture and heating in cooking process , and it is much easier for getting soybean oil in the oil pressing process.

6. Cooker: This machine can adjust the water content in oil seeds. It’s also good for the oil pressing and solvent extraction section.

7. Press: The press machine is used to most of the oil in oilr seeds.

8. solvent extraction equipment: after prepressing there is still oil left iin oil recake, a solvent extraction machine can be used to extract the oil in oil cake, then oil loss will be less than 1%.

9. Oil refinery equipment: it is used to refine crude oil, remove the impurities, FFA, strange odors in crude oil and get to first grade cooking oil.

Technology Leadership: Patented technologies for soybean oil processing.

Experience: Completion of numerous large-scale soybean oil projects globally.

Customized Service: Personalized solutions based on customer needs.

After-sales Service: Global service network for quick response.

High Cost Performance: Competitive pricing compared to international brands.