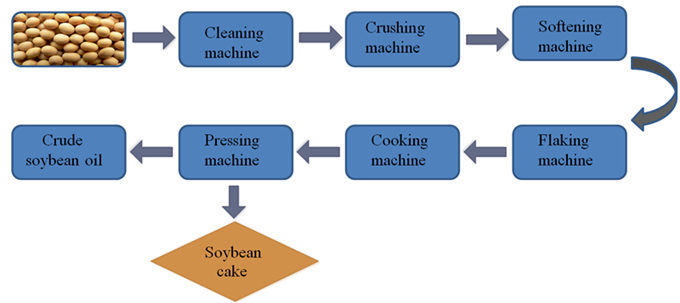

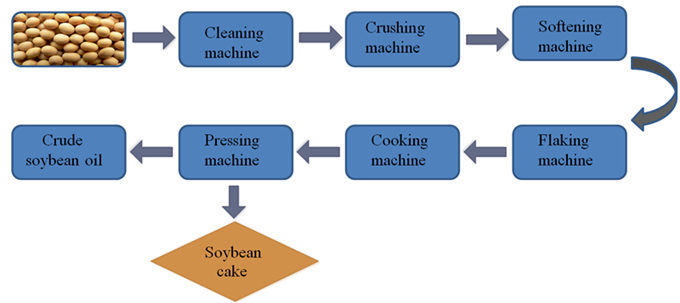

A soybean oil processing mill typically involves several stages: seed cleaning, dehulling, flaking, cooking (or conditioning), pressing/extraction, and refining. The process can vary slightly depending on whether mechanical pressing or solvent extraction is used.

1. Seed Cleaning and Preparation:

Cleaning:

Soybeans are cleaned to remove impurities like stones, dirt, and other debris.

Dehulling:

The hulls (outer layers) of the soybeans are removed, which can improve oil yield and quality.

Crushing/Flaking:

Soybeans are crushed into flakes to increase the surface area for oil extraction.

2. Oil Extraction:

Mechanical Pressing:

The flakes are passed through a screw press, which applies mechanical pressure to extract the oil. This method is often used in smaller-scale operations.

Solvent Extraction:

Soybeans are soaked in a solvent (like hexane) to dissolve the oil. The solvent is then evaporated, leaving the oil behind. Solvent extraction is common in large-scale, high-throughput operations.

3. Oil Refining:

Degumming: Removes phospholipids and other impurities.

Neutralization: Removes free fatty acids.

Bleaching: Removes pigments and other undesirable colors.

Deodorization: Removes volatile compounds that can affect the taste and smell of the oil.

4. Other Processes:

Cooking/Conditioning: Heated and/or steamed to prepare the soybeans for pressing or solvent extraction.

Filtration: Removes any remaining solids from the extracted oil.

Hydrogenation: (Optional) May be used to alter the melting point of the oil for specific applications.

A Business Strategy for Soybean Oil Production

Establishing a soybean oil processing plant for commercial purposes might be a financially rewarding option for those who plan to start a business in the edible oil production line industry. Here, a complete business plan for a soybean oil processing plant is available. It will be very useful to consider these guidelines when starting out. Hence, it’s a good idea to keep these tips in mind.

Raw Material Sourcing and Management:

- Secure reliable soybean suppliers: Establish long-term relationships with suppliers to ensure a consistent and high-quality supply of soybeans.

- Strategic location: Choose a site with easy access to soybean sources, transportation infrastructure, and target markets to minimize distribution costs.

- Inventory management: Implement systems for managing soybean inventory, including proper storage to maintain quality and prevent spoilage.

Production Process Optimization:

- Plant layout: Design a layout that optimizes workflow, minimizes material handling, and ensures efficient production.

- Equipment selection: Invest in high-quality, corrosion-resistant machinery that is specifically designed for soybean oil processing.

- Process control: Implement measures to control temperature, pressure, and other variables during the extraction and refining process to maximize oil yield and quality.

- Safety and environmental compliance: Prioritize safety protocols throughout the production process and adhere to environmental regulations.

- Quality control: Establish a comprehensive quality control system to ensure that the final soybean oil meets the required standards.

Distribution and Marketing:

- Identify target markets: Determine the best channels for distributing soybean oil, including wholesale, retail, or direct-to-consumer.

- Develop a marketing strategy: Create a plan to promote the soybean oil, highlighting its quality and benefits.

- Logistics and delivery: Establish efficient systems for transporting the soybean oil to customers.

Financial Management:

- Cost analysis: Thoroughly analyze the costs associated with setting up and operating the soybean oil production plant.

- Funding options: Explore various funding options, including loans, grants, or private investment, to secure the necessary capital.Conduct a profitability analysis to ensure the business is sustainable and generates a positive return on investment.

Human Resources:

- Staffing: Hire qualified personnel with expertise in soybean oil production, including mechanical engineers, operators, and quality control specialists.

- Training: Provide adequate training to ensure employees understand the production process and safety procedures.

- Employee retention: Implement strategies to retain skilled employees and minimize turnover.