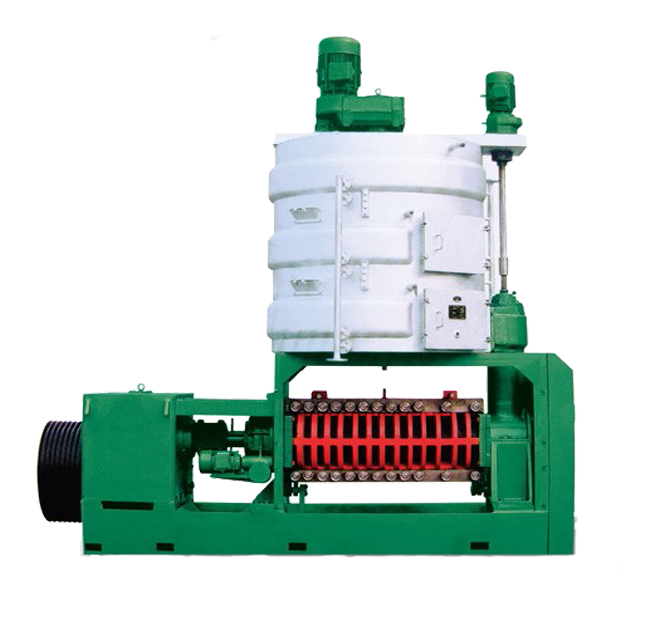

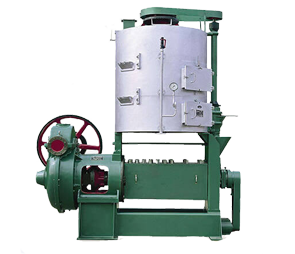

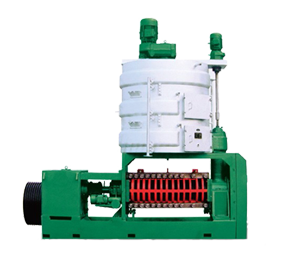

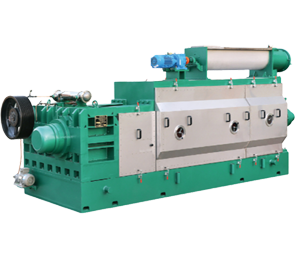

Model ZY28 screw oi press is the larger continuous pre-press and one-time pressing equipment in China. Its characteristics are high capacity, low power consumption, low cost in running, the construction of the press cake is soft but not fragmentary, and the solvent is apt to infiltrate, lower oil in cake. It’s the excellent choose of press equipment for the large and medium-sized oil factory.

Processing Capacity: 120-150 T/D

Processing Capacity: 120-150 T/D Residual Oil Rate: 16-20%

Residual Oil Rate: 16-20%

all machine can be customized according to customers' needs.

Model ZY28 screw oil press is the larger continuous pre-press and one-time pressing equipment in China, which is widely used to press the seeds containing more oil such as the cottonseed kernels, rape seed, tung seed maize embryo and peanut kemels, lt has the following advantages: high processing ability; low power consumption; low operation expense, defatted cake being loose but not crushed, easy to sovent penetration; low residual oil rate. Such equipment is the ideal oil pressing equipment for the large and medium-sized oil processing plant.

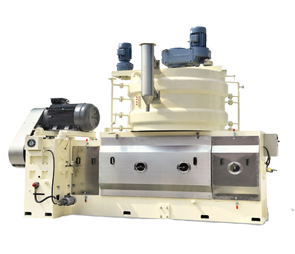

1. The screw cold oil press machine is an upgraded product of the original Type 28 oil press. Compared with the original model, a hollow shaft water-cooling device is added to avoid cake paste. The feeding mode is changed to reverse feeding, and the gearbox is an up-and-down opening and closing box.

2. The pressed cake has good shaping effect and good color, which is conducive to leaching.

3. This equipment has a wide adaptability range, and the requirements for moisture and temperature are not too strict. It is also a high and low temperature dual-purpose machine. Even if the material temperature is pressed under low temperature conditions of 70-80 degrees, it will not affect the residual oil index of the dry cake. It can ensure low denaturation of protein in the cake.

4. The main gearbox gear is equipped with a cold oil circulation spray device to fully lubricate the gearbox bearings and gears and greatly extend their service life.

QIE Machinery is a professional soybean oil mill plant machine manufacturer. We can provide soybean oil expeller machine, large scale soybean oil mill plant, automatic soybean oil mill plant and soybean oil refinery machine, turnkey soybean oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

| Model | ZY28 |

| Processing Capacity | 120-150 t/d |

| Residual Oil Rate of Cake | 16-20 % |

| Power Matching | 75+11+4.0 kw |

| Overall Dimensions(L×W×H) | 3740×1920×3843 mm |

| Weight | 9160 kg |

Years of development have brought customers from all over the world. Contact us to start customizing a soybean oil production line for your business.

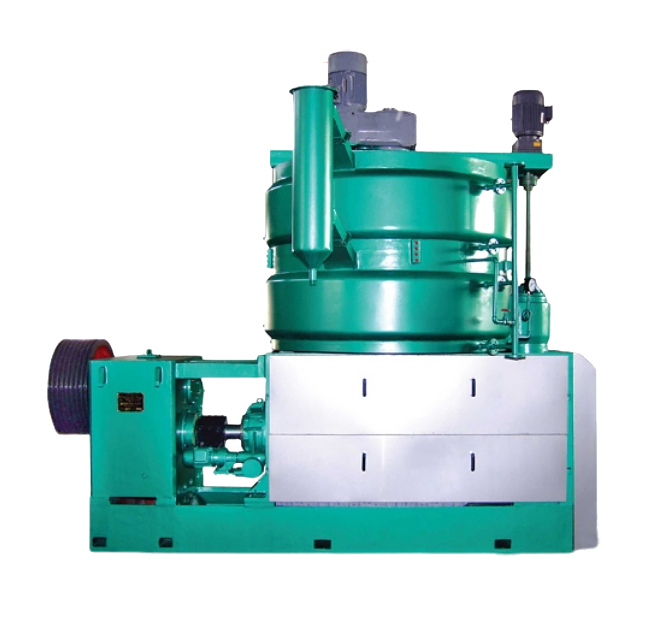

This series of machine is mainly composed of five parts: automatic control part, heating and pressing part, adjusting part, transmission part and vacuum oil filtering part.

1. Automatic Control System: air switch, AC contactor, temperature controller, automatic circuit protection system, etc.

2. Heating and Pressing Part: Heater, screw and strip, machine body assembly, etc.

3. Transmission Part: main shaft and speed reducer, belt wheel, motor wheel, etc.

4. Adjustment Part: adjusting screw, adjusting nut, sub-handle, lock nut, etc.

5. Vacuum Oil Filtering Part: vacuum pump, oil filtering drum pipeline assembly.

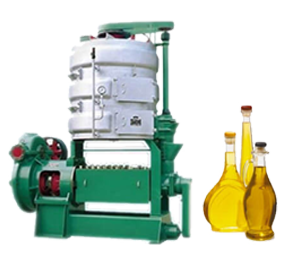

The power is transmitted to the main shaft through a reduction mechanism. As the screw press on the main shaft rotates, it continuously pushes the oil-bearing materials forward through the threads. Due to the gradual reduction of space between the press chamber and the screw, the density of the oilseeds increases, which in turn causes a continuous rise in pressure during the pressing process.

During this stage, the oil press machine utilizes an automatic temperature control system to heat the main body of the equipment. This automated heating process not only reduces labor intensity but also minimizes wear and tear on the machine, saving electricity and time. As the screw rotates, friction occurs between the oilseeds and the mechanical components, generating heat. This combination of pressure and heat plays a crucial role in breaking down the cellular structure of the oilseeds, forcing the oil to be expelled. The oil then flows through the oil channels, while the residual oil cake is discharged from the cake outlet.

As the oil flows out, it is collected in an oil pan and directed into the oil filtering barrel. The vacuum pump extracts air from the barrel, creating negative pressure. This vacuum effect forces the oil to pass through the filter cloth, leaving any oil residue trapped on the surface. What remains is pure, high-quality oil.

Our soybean oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the soybean oil production equipment and soybean oil production lines we manufacture. Whether you need a single soybean oil production equipment or a complete soybean oil production line, we can customize it for you.

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Egypt

Production Output : 300TPD

Raw Materials : Soybean

Country : Serbia

Production Output : 200TPD

Raw Materials : Soybean

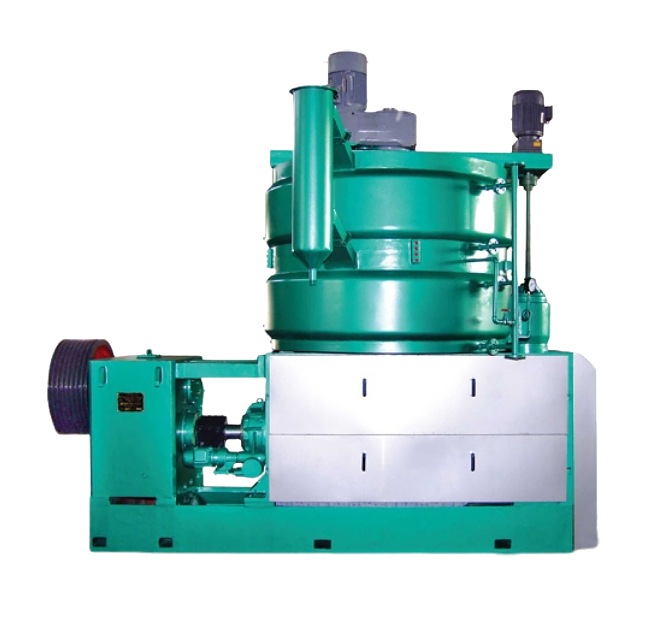

The ZX series operates on the principle of mechanical pressing. It has a screw shaft within a press cage. As the screw shaft rotates, it conveys the pre - treated oilseeds through the press cage. The pitch of the screw gradually decreases, and the space between the screw and the cage bars also narrows. This causes the oilseeds to be compressed. The pressure generated forces the oil out of the seeds, which then seeps through the gaps in the cage bars. Before pressing, many models in the ZX series are equipped with a steaming wok. This allows for the adjustment of the moisture and temperature of the oilseed material embryo. For example, the appropriate moisture content for most seeds is around 8 - 12%, and the temperature can be adjusted to 60 - 80°C, which softens the seeds and improves oil extraction efficiency. The process from feeding the seeds, steaming and cooking them (if applicable), to discharging the oil and forming the cake is continuous and automatic in most ZX series models.

Screw oil presses are highly versatile and can process most oil-rich seeds, including:

The machine’s performance depends on seed preparation (e.g., dehulling for sunflower seeds, moisture adjustment for soybeans) and press settings (e.g., screw speed, cage tightness). Some models are optimized for specific seeds (e.g., cold-press screws for sesame), but most are adjustable for multi-seed use.

Oil yield depends on the seed type, preparation, and machine quality, but typical ranges are:

Screw presses generally achieve 70–90% of the seed’s total oil content. For example, soybeans with 20% oil content yield 14–18% oil (residual oil in the cake is 2–6%). Hot-pressing often increases yield by 2–5% compared to cold-pressing due to better oil flow at higher temperatures.

Seed preparation: Proper cleaning (removing stones/dirt) prevents equipment damage; conditioning (moisture 8–12%, temperature 60–80°C) softens seeds for better oil release.

Screw design: The screw’s pitch, diameter, and compression ratio (ratio of initial to final volume) determine pressure. A steeper compression ratio (e.g., 1:8) increases yield but requires more power.

Operating parameters: Screw speed (50–200 rpm) affects residence time—slower speeds allow more thorough pressing but reduce throughput.

Maintenance: Worn screws or clogged cage slots reduce pressure and yield; regular cleaning and lubrication prevent inefficiencies.

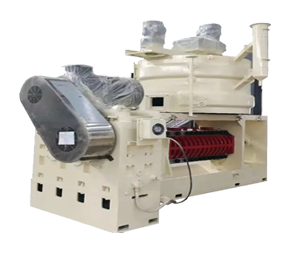

Large-scale oil presses are engineered for efficiency, automation, and durability, with key differences including:

Power consumption scales with capacity, but large-scale presses typically require 50–500 kW of electrical power, with additional energy for auxiliary systems:

Large-scale presses are part of integrated systems that include:

Integration is managed via PLCs, which synchronize all stages to maintain consistent flow—e.g., adjusting feed rate if the press slows down to prevent bottlenecks.

Consistency control: Maintaining uniform seed quality (moisture, purity) across large batches is critical—variations can reduce yield by 2–5%.

Energy costs: Fluctuations in electricity or fuel prices impact profitability; many plants use on-site renewable energy (solar, biomass) to mitigate this.

Regulatory compliance: Meeting food safety standards (e.g., EU REACH, FDA) for oil purity and worker safety (OSHA, ISO 45001) requires ongoing investment in testing and training.

Downtime risk: A single breakdown can halt the entire line, so plants often have backup presses or redundant systems for critical components.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of soybean oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for soybean oil production. Customize the soybean oil processing equipment capacity according the different customers requirements.