The 100TPD Soybean Oil Solvent Extraction Plant is designed for high-efficiency oil extraction from various oil cakes, featuring automatic operation and energy-saving benefits. Made from carbon steel and stainless steel, it ensures durability with a long service life. The plant supports large-scale edible oil production, meeting industrial demands with capacities ranging from 5-500T D. It includes advanced components like pressure vessels and motors, backed by over 5 years of warranty on core parts.

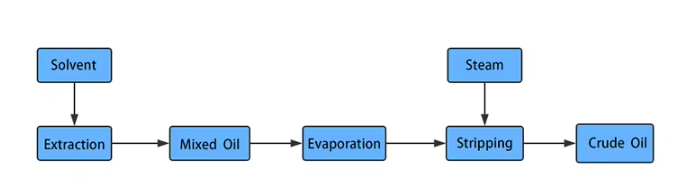

Soybean Oil Solvent Extraction adopts grease solvent to extract oil. In the extraction process solvent and soybean oil form into miscella, then separate solvent and soybean oil by high temperature steaming, stripping, condensing recollecting. But there is still little solvent in crude oil, so the soybean oil refining equipment is necessary after soybean oil solvent extraction plant. The oil after refined is more pure and suitable for cooking in high temperature.

soybean cake→ solvent extraction→miscella evaporation→steam stripping→wet meal evaporation→solvent gas condensation→tail gas recovery→crude soybean oil.

1). Solvent Extraction Procedure

The soybean flakes gets into the extractor through feeding scraper, the materials run a circle from the feed inlet to discharge outlet in the extractor. Spraying the extruded rice bran with the concentrate diminishing miscella between the feed inlet to discharge outlet. Then before getting into the drain off section, spraying again with fresh solvent, the drained wet meal discharges into the wet meal scraper from the extractor’s discharge grid through kick-out device. The concentrated miscella gets into the two-stage hydrocyclone from the pump, to remove the powder impurities, finally get into the miscella tank.

2). Desolventizing Procedure

The solvent contain wet meal that from the extractor are sent to the DTDC desolventizer’s pre-desolventizing layer by scraper through air locker, the bottom is heated by indirect steam to remove part of solvent; then the pre-desolventized wet meal get into the desolventizing layer, there are automatic control on the desolventizing layer to keep certain thickness of materials, then the bottom gets into the direct steam to remove all the solvent, at same time some steam condense in the meal, the moisture content of meal will sectional rise. The desolventized meal falls onto the drying layer quantitative through rotary valve, the drying layer keeps certain materials level, then process the drying procedure, after drying get into the cooling layer to lower down the temperature, finally discharge the finished meal through automatic flow controlling gate, then though the scraper to transport the meal to warehouse.

3). Evaporation Procedure

The miscella gets into the first long tube evaporation pass from the miscella tank, the evaporated solvent gets into the evaporation condenser through separation chamber, there are liquid level controlling device on the separation chamber’s outlet pipeline to keep the liquid seal, the miscella that after first evaporation concentration gets into the second long tube evaporator for evaporating process. The shell pas is heated by indirect steam, the evaporated solvent vapor gets into evaporation condenser through separation chamber, there are liquid level controlling device on the separation chamber’s outlet pipeline to keep the liquid seal. The miscella gets into the stripping tower’s disks from the top of the tower, then fall down layer by layer, meanwhile jet direct steam from the bottom of tower to remove the residue solvent.

4). Solvent Condensation and Water Separation Procedure

The liquor condensate that from evaporation condenser, energy saver condenser and steam stripping condenser is collected together then through recovery pump to inject them into water segregator. The end condensed steam enter into the energy saver condenser, the energy saver’s liquor condensate and first evaporation shell pass’s liquor condensate get into the water segregator directly. The free gas of energy saver condenser,tripping condenser, water segregator and solvent library together enter into the final condenser, the end steam from final condenser is absorbed by paraffin recovery device.

5). Tail Gas Absorption Procedure

The non condensed vapor from extraction evaporator, DT evaporator, oil stripper, cooking pot, water segregator and underground solvent tank, get into the final condenser for recovering the solvent, the non condensed vapor from the final condenser gets into the mineral oil recovery device, the free gas are discharged into air through fire barrier.

| Moisture of extraction material | 5-8% |

| temperature of extraction material | 50-55°C |

| oil content of extraction material | 14-18% |

| thickness of extraction cake | less than 13mm |

| powder porosity of extraction material | less than 15% (30 mesh) |

| solvent | national standard No. 6 solvent oil |

| volume of supplement water | 1-2m/t raw material |

1) Solvent pumps: continuously spray solvent to the Rotocel extractor.

2) Rotocel extractor: The pre-pressed cake is sprayed and soaked with a solvent to dissolve the oil in the solvent (to form

miscella). After processing, wet powder and miscella (mixed oil) are obtained.

3) DTDC: used to separate the solvent from the wet meal.

4) Miscella tank 1st: pump the miscella (oil with solvent) into the miscella 1st, then add 10% saline water to it. The

phospholipids and impurities in the miscella will react with the saline water, at last the reactant precipitate, reaching the goal of purifying.

5) Miscella tank 2nd: the purified miscella will be pumped into it.

6) Miscella stripping: it will remove the remaining solvent in miscella. And the solvent will be discharged to condenser for

recycling.

7) Condenser: used to cool the solvent gas separated from the wet meal and miscella for recycling.

100TPD Soybean Oil Solvent Extraction Plant Main Machine List:

| No. | Name | Qu’ty (set) |

Unit power(KW) | Total power(KW) |

|

1

|

Buffer hopper | 1 | 0.0 | 0.0 |

|

2

|

scraper conveyor | 3 | 5.5 | 16.5 |

|

3

|

Sealed screw conveyor | 2 | 2.2 | 4.4 |

|

4

|

Rotocel extractor | 1 | 2.2 | 2.2 |

|

5

|

Mixing oil heater | 6 | 0.0 | 0.0 |

|

6

|

Fresh solvent high level tank | 1 | 0.0 | 0.0 |

|

7

|

Miscella temporary storage tank | 1 | 0.0 | 0.0 |

|

8

|

Miscella filter | 1 | 0.0 | 0.0 |

|

9

|

Catcher | 1 | 0.0 | 0.0 |

|

10

|

Vertical desolventizer-toaster | 1 | 31.5 | 31.5 |

|

11

|

Cyclone | 1 | 2.2 | 2.2 |

|

12

|

Steam heater | 2 | 0.0 | 0.0 |

|

13

|

Solvent heater | 1 | 0.0 | 0.0 |

|

14

|

Steam distribution cylinder | 1 | 0.0 | 0.0 |

|

15

|

evaporator | 2 | 0.0 | 0.0 |

|

16

|

Layer-disc type steam-stripping tower | 1 | 0.0 | 0.0 |

|

17

|

Solvent turnover warehouse | 1 | 0.0 | 0.0 |

|

18

|

condenser | 6 | 0.0 | 0.0 |

|

19

|

Water absorption tower | 1 | 0.0 | 0.0 |

|

20

|

Water bath energy-saving exhaust gas recovery device | 1 | 0.0 | 0.0 |

|

21

|

tanks | 6 | 0.0 | 0.0 |

|

22

|

Cooling tower | 1 |