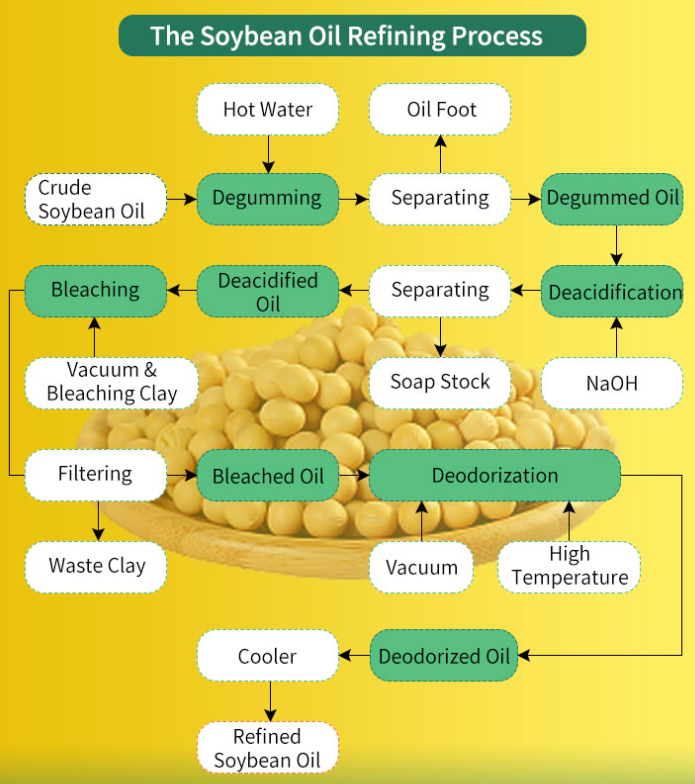

Our Continuous Soybean Oil Refinery Plant, with capacities ranging from 20TPD to 5,000 TPD, is designed for high-capacity oil refining, ensuring efficiency, consistency, and high-quality output. This type of Soybean Oil Refinery Plant is ideal for large-scale edible oil production lines. It is designed to handle various crude oils, offering customized solutions and leveraging chemical and physical refining technologies to meet diverse production needs.

Brand

QIE

Raw Material

Crude Soybean Oil

Capacity

20-5000TPD

20-5000TPD

Customized Large Continuous Soybean Oil Refinery Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

A large continuous soyebean oil refinery plant consists of multiple sophisticated equipment and systems to ensure efficient, high-capacity processing of crude soybean oil into refined soybean oil. The equipment is interconnected to provide a seamless, continuous operation, maximizing productivity and maintaining consistent quality. The integration of advanced technology, automated systems, and energy-efficient equipment ensures that large volumes of crude soybean oil can be processed into high-quality refined soybean oil.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed soybean oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes soybean oil and soybean protein production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This project includes 300TPD soybean pre-treatment+solvent extraction+30TPD oil refinery plant.

Learn More

This project includes 300TPD soybean pre-treatment+solvent extraction+60TPD oil refinery plant.

Learn More

This is our soybean protein isolate project with low temperature desolventing technology in Serbia.

Learn More

The 200TPD soybean oil project is for our Russian customer.The workshop adopts pretreatment, solvent extraction and refining process.

Learn MoreAbsolutely. Our team will assess your production volume, budget, and efficiency requirements to recommend the best edible oil refining process to meet your needs. Contact us to get a free consultation now!

Mechanical pressing is ideal for seeds with high oil content, extracting oil by physically pressing the seeds. Solvent extraction, better for low-oil-content seeds, uses a solvent to dissolve the oil, maximizing yield and efficiency.

Absolutely. Our after-sales team is available for ongoing support, remote troubleshooting, and on-site assistance as needed to keep your edible oil mill plant running smoothly.

Routine maintenance includes lubrication, cleaning, and regular inspection of key components, such as press machinery and filtration systems. We provide detailed maintenance instructions for each piece of equipment.

Costs depend on factors like production capacity, equipment type, refining complexity, and level of automation. We offer budget-friendly solutions for small-scale setups as well as full-scale industrial soybean oil mill plants.

Key factors include proximity to raw materials, access to utilities, transportation options, regulatory environment, and labor availability. We assist with location selection based on production requirements and logistical considerations.